9

ACCU-TURN MULTI-SPEED BRAKE LATHE

OPERATION PROCEDURES

OPERATION

The 8944 Multi-Speed Lathe has multiple spindle speeds and

infinitely variable cross feeds (.001 to .010 per revolution) to

accommodate a wide range of machining tasks. It is important to

remember that the desired surface finish depends on the correct

relationship of the spindle speed with the cross feed speed. As a

general rule, slower spindle speeds require slower cross feed

speeds. Also deeper cuts normally dictate that a slower cross feed

rate and/or spindle speed may be necessary.

Multi-Speed Settings

The 8944 Multi-Speed Brake Lathe has three different pulley

selections.

(1)

The small pulley at the motor in conjunction with the large

pulley at the gear box drives the spindle at 100 RPM's. This

speed is recommended on large diameter drums, rotors, and most

flywheels; the cross feed rate should be set at a slow

setting. Position feed rate indicator between "0" and "3".

(2)

The middle pulleys rotate the spindle at 150 RPM's and are

normally used to machine intermediate size rotors and drums

that have a larger diameter than most used on passenger cars.

At this spindle RPM, cross feed can be set at a slow to medium

feed rate. Position feed rate indicator between "2" and "5".

(3)

The large pulley at the motor and the small pulley at the gear

box allows the spindle to rotate at 200 RPM's. This spindle

speed should be satisfactory for most passenger car drums and

rotors. The cross feed speed may be set at a variety of rates

from slow to fast to produce the desired finish. Position the

feed rate indicator between "3" and "8".

Note: High pitch squeals may occur if cross feed rates are set too

slow. It may be necessary to advance the cross feed rate slowly to

eliminate the noise. If chatter occurs, the cross feed rate should

be adjusted to a slower feed rate.

Summary of Contents for 8944

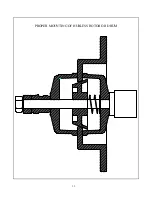

Page 18: ...15 PROPER MOUNTING OF HUBLESS ROTOR OR DRUM ...

Page 19: ...16 PROPER MOUNTING OF HUBBED ROTOR OR DRUM ...

Page 20: ...17 PROPER MOUNTING OF FLYWHEEL ...

Page 28: ......

Page 29: ...26 ...

Page 30: ...27 ...

Page 31: ...28 ...

Page 32: ...29 ...

Page 33: ...30 ...

Page 34: ...31 ...

Page 35: ...32 ...

Page 36: ......

Page 37: ...33 ...