11

cycle, single phase. Check electrical input plate on rear of

machine. The Off-On switch is located to the right end of the main

housing. Never operate machine unless power supply agrees with

electrical plate rating and machine is properly grounded.

ACCU-TURN 8944 MULTI-SPEED BRAKE LATHE

MOUNTING AND MACHINING PROCEDURES

Inspection of Brake Drums, Disc Rotors & Flywheels Before

Machining

IMPORTANT: The maximum amount of metal removed from the

finished workpiece should never exceed the manufacturer's

specifications. It is dangerous to operate a vehicle with a drum,

rotor or flywheel which has had more material removed than is

allowed. Proper operation cannot be established if these

specifications have been exceeded. ACCU Industries recommends that

each workpiece be checked for size before mounting on the lathe and

after machining.

Mounting Hubless Drums or Rotors

1.

Clean and check all surfaces for flatness that will come in

contact with centering cones and/or bell clamps to ensure

solid mounting.

2.

Cleaning and properly mounting the drum or rotor prior to

machining will ensure a minimum of stock removal, better

surface finish and optimum braking efficiency.

3.

Excessive run out or wobble of the drum or rotor after it has

been properly cleaned and mounted on the arbor may indicate

severe damage to the drum or rotor. These drums or rotors

should not be

used for further service.

Summary of Contents for 8944

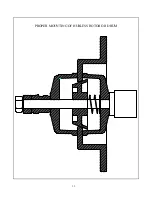

Page 18: ...15 PROPER MOUNTING OF HUBLESS ROTOR OR DRUM ...

Page 19: ...16 PROPER MOUNTING OF HUBBED ROTOR OR DRUM ...

Page 20: ...17 PROPER MOUNTING OF FLYWHEEL ...

Page 28: ......

Page 29: ...26 ...

Page 30: ...27 ...

Page 31: ...28 ...

Page 32: ...29 ...

Page 33: ...30 ...

Page 34: ...31 ...

Page 35: ...32 ...

Page 36: ......

Page 37: ...33 ...