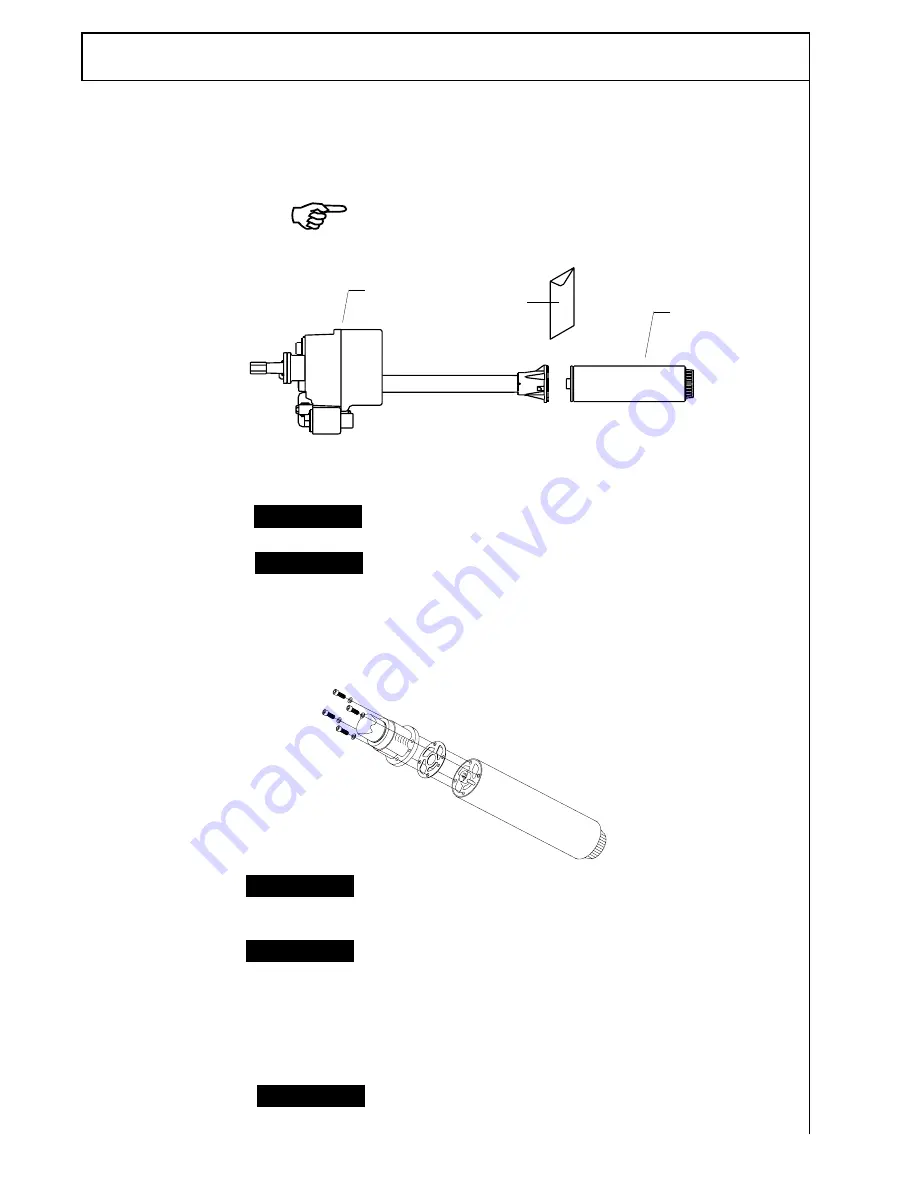

Figure 2.2 Aligning the gasket

PACKER/MANIFOLD

WITH PIPING

UMP

KIT (144-328-4)

Figure 2.1 Attaching the UMP

The attachment hardware kit to be used to connect the UMP to the Packer/Manifold

assembly piping consists of four Grade 8 5/16-18 socket head cap screws, four 5/16

spring lock washers, and one discharge head gasket. It is identified by the kit number

144-328-4 marked on the bag.

Suggested tools (non-sparking): 3/4” wrench, pipe wrench,

1/4” allen wrench, 9/16” wrench, screw driver, wire cutter and

wire stripper.

1:

Place the new gasket on the new UMP so that all the holes align.

Gaskets from competitive UMPS will not seal properly and

performance will be reduced.

Visually inspect the pigtail connector in the discharge head.

Replace if damaged. Be certain the indexing tab of the pigtail

is seated in the notch of the discharge head.

2:

Lubricate the o-ring and pigtail with petroleum based jelly.

3:

Align the UMP positioning dowel and boss with the proper holes in the discharge

head and push the UMP into position using hand force only. The UMP should be

snug against the discharge head prior to installing the UMP retaining bolts.

Use hand force to put the UMP on the discharge head. If the

UMP does not seat properly, snug against the discharge head,

remove the UMP and correct the problem.

Do not use the bolts to pull the UMP into position. Use the

cross pattern to snug and torque bolts. Do not over torque the

bolts. Not following these instructions may cause parts to fail.

4:

Install the UMP retaining bolts and lock washers. Snug and then torque the bolts

using a cross pattern. Torque to 7 ft-lb. (11 N•m).

I

NSTALLING THE

P

UMP

Red Jacket petroleum pumps are designed to operate in

Class 1, Group D locations.

NOTICE

NOTICE

NOTICE

— 10 —

4” Petroleum & AG

CAUTION

NOTICE

Summary of Contents for Red Jacket AGUMP33R1

Page 14: ...8 4 Petroleum AG...