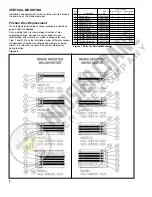

Figure 5

Armature Replacement

CAUTION: Load to be removed or blocked. Brake

will

be

inoperative during this procedure.

If you replace the magnet assembly, it may be necessary to

replace the armature (15J). If it is badly deformed, it will be

difficult to make the magnet quiet.

1. To replace, remove operator assembly (15) from

brake. See “Friction Disc Replacement Steps 1-3” on

page 5.

Remove nuts (15T), springs (15S) and carriage bolts

(15R). This will allow the armature plate assembly to

be removed from magnet bracket.

2. Remove screw (15Q), lockwasher (15P), locking

plate (15N), two screws (15M), spacers (15L), and

armature (15J). Inspect these parts and shock mount

(15K). If worn, replace them also.

3. Put armature in place (ground side up) and install

spacers (15L) and screws (15M).

NOTE: See Fig. 5 Screws (15M) should be tightened

to remove slack only. Then back off, counterclockwise

on screw so that the next flat on screw is parallel

with edge of the armature plate (15F).

Install locking plate (15N), screw (15Q), and lock-

washer (15P). Tighten screw with 30 lb. in. torque.

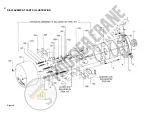

4. Reassemble to magnet bracket (15C) using items

(15R), (15S) and (15T). Reassemble operator

assembly to brake bracket. Set magnet air gap “A”

and set torque springs (15S) to 1” as shown in Fig. 3.

Pivot Stud Adjustment

CAUTION: Load to be removed or blocked. Brake

will

be

inoperative during this procedure.

This adjustment is made at the factory and may be required

when replacing the magnet assembly (15A) or the armature

(15J).

The purpose is to regulate the height of the armature plate

(15F) so that when the magnet (15A) is energized, the

armature (15J) is parallel with it. This is required so that

the magnet will be quiet.

NOTE: Cover (20) must be removed to make this adjustment.

1. To adjust: Hold nut (19) which is adjacent to washer

(18) and loosen the other nut (19) and remove it from

the stud.

2. Energize the magnet and turn remaining nut (19)

counterclockwise slowly until the magnet becomes

noisy. Turn magnet on and off several times until you

find the position where the magnet first becomes

quiet.

At this point, turn nut (19) 1/3 turn (two flats) in a

clockwise position. Hold nut in this position and turn

magnet on and off to make sure the magnet does not

become noisy.

3. Holding this nut in place, screw on other nut and

tighten it against the nut you are holding. Tighten

firmly.

4. Operate the manual release. If the release does not

operate properly, see “Manual Release Adjustment”

on next page.

6

Summary of Contents for LOUDEN 200 Series

Page 1: ......

Page 2: ......

Page 3: ......

Page 4: ......

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ......

Page 9: ...FIGURE 8 FIGURE 9 FIGURE 10 FIGURE 11...

Page 10: ......

Page 11: ......

Page 12: ......

Page 13: ......

Page 14: ......

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......

Page 96: ......

Page 97: ......

Page 98: ......

Page 99: ......

Page 100: ......

Page 101: ......

Page 102: ......

Page 103: ......

Page 104: ......

Page 105: ......

Page 106: ......

Page 107: ......

Page 108: ......