WVD100

Product Manual

WVD100, Rev 2.5E

Page 4

EZ

Loop

Quick Start

5. Activate & Test Sensor:

Activate and test the sensor next to the AP100 and antenna

before installing the sensor to insure the sensor is working

correctly. To activate the sensor:

1. Place the Sensor on the ground so it is close to the antenna and has a

clear line of sight. Do not move the Sensor once it is Active.

2. Program the Sensor Active on the AP100:

a. Select PROGRAM, press Enter

b. Select SENSOR, press Enter

c. Select ACTIVE, press Enter

d. Select the Sensor to activate, press Enter

e. Select ACTIVE, press Enter

f. Hold the Enter button to exit programming

3. Without moving the sensor, test the sensor:

a. Place the sensor near the antenna to ensure good communication.

b. Do Not Move The Sensor or it will cause a locked on detect.

c. Place an object such as a magnetized screwdriver, cell phone or

piece of metal right next to the sensor. The Sensor should detect.

d. Remove the object. The Sensor should drop detect.

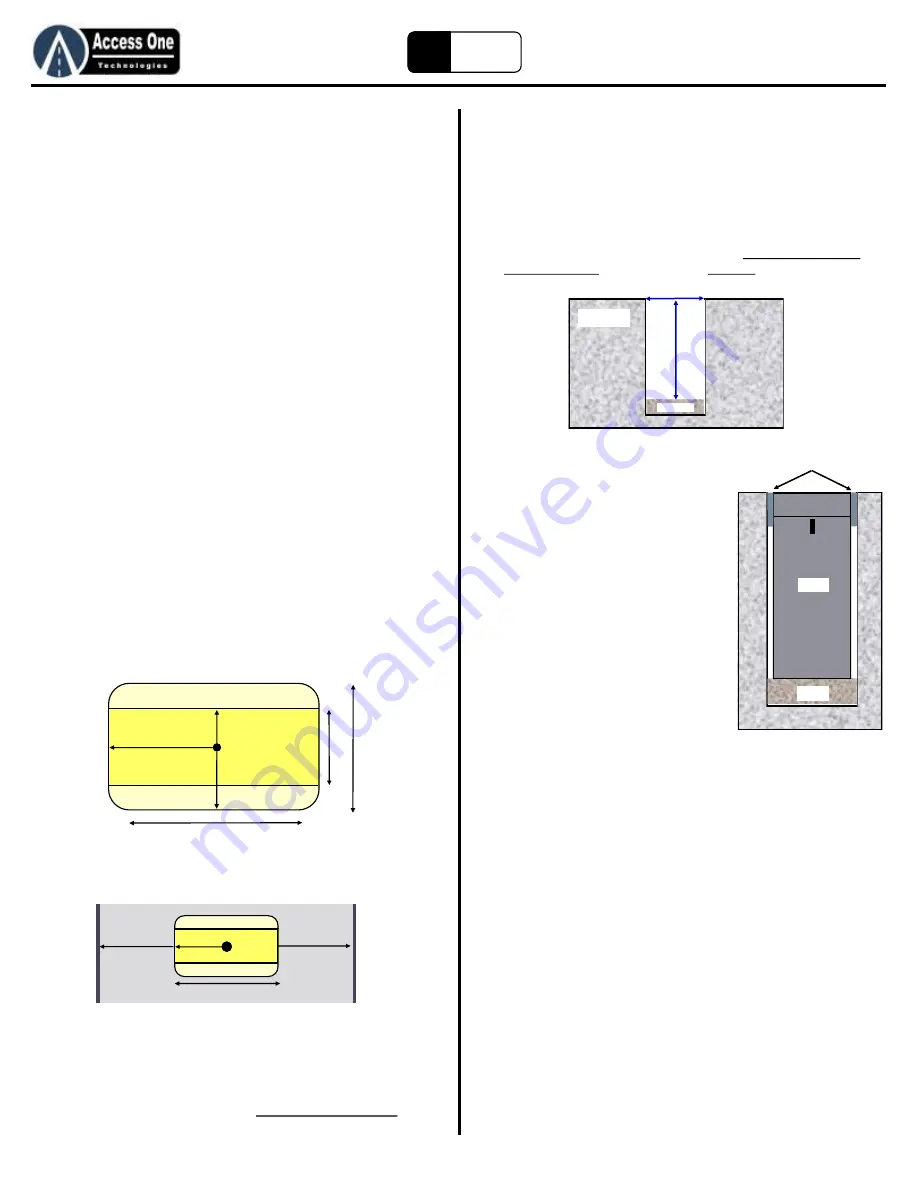

6. Select Sensor Location:

Detection range is similar to a rectangular bubble around the

sensor. Average detection distance from the sensor is

approximately 8ft wide x 4ft deep x 3-4ft high. In some occasions

the distance may be less and in some occasions the distance may

more. A simple above ground test can help define the distance.

To layout a standard gate application:

1. Place the sensor in the center of the traffic lane.

2. Determine if one or multiple sensors will be needed for full detection

across a wide traffic lane.

3. When a sensor is placed on the side of the driveway, make sure it

reaches far enough into the lane to detect a vehicle.

4. Place the sensor far enough away from the gate so the moving gate

does not activate the sensor. Usually 8-10 feet from the gate.

Quick Start

7. Drill Sensor Hole:

To prepare the Sensor hole for installation:

1. Drill a 2” wide hole 5” deep. (Tip: Use a Dry Diamond Core Bit to core

drill the hole)

2. If the hole is more than 5” deep, add sand to make the sensor flush

with the top of the

driveway.

8. Install Sensor:

To install the Sensor in the driveway:

1. Close the Sensor housing tightly making

sure the top has sealed against the O-

rings.

2. Place the sensor in the hole with the line

on the housing facing toward the

gate and traffic lane.

3. Secure the housing in the driveway with a

sealant. The Sensor needs to be secured

so that it does not turn when a vehicle

drives over it.

9. Reset Sensor Active:

If a Sensor is Active and then moved, it will detect and lock on

detect until it is reset. It will automatically reset after 14 minutes

or it can be reset by making it Active again. To reset the Sensor:

1. Program the Sensor Active on the AP100:

a. Select PROGRAM, press Enter

b. Select SENSOR, press Enter

c. Select ACTIVE, press Enter

d. Select the Sensor to activate, press Enter

e. Select ACTIVE, press Enter

f. Wait for the AP100 to go to LEARN

g. Hold the Enter button to exit programming

2. Wait up to 2 minutes for the sensor to reset:

a. When the Sensor is reset, it will drop detect and the relay should

turn off.

3. If the sensor gets moved when sealing it, simply reset it again.

IMPORTANT: Read the entire manual for complete and

proper safety, installation and programming instructions.

6-8 feet Side to Side

3-4 feet

2-

3 f

ee

t

1-

2 f

t

Expanded Area

Expanded Area

Initial

Detection

Area

2-

4 f

ee

t

4-

6 f

ee

t

5 feet

5 feet

or less

3 - 4

feet

6 - 8 feet detection

Sand

Driveway

5”

D

ee

p

2” Wide

Sand

Sensor

Sealant

Summary of Contents for WVD100

Page 24: ...www AccessOneTechnologies com...