WVD100

Product Manual

WVD100, Rev 2.5E

Page 22

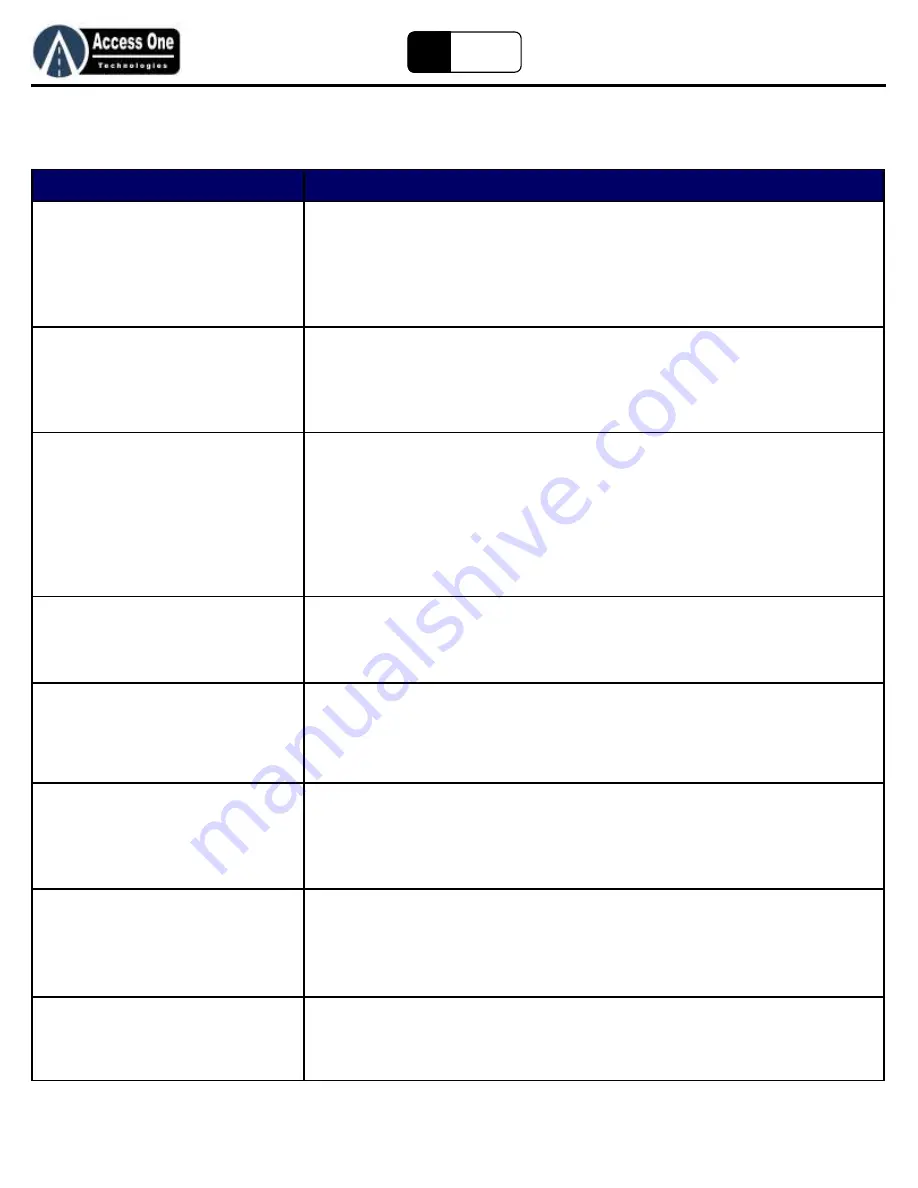

EZ

Loop

S

YMPTOM

:

P

OSSIBLE

S

OLUTION

:

AP100 does not appear to have power

1. If the AP100 is powered by a gate operator, make sure the operator power is on

2. Check the connections for clean tight connections.

3. Check the fuse on the AP100.

4. Test the power level using a VOM meter at the supply power.

5. Test the power level using a VOM meter at the AP100.

Sensor does not appear to have power

1. Make sure the battery is tightly plugged on

2. Test the battery power using a VOM meter

3. Battery power should be between 3.3VDC - 3.6VDC

4. Replace the battery

Sensor will not learn

1. Make sure the AP100 antenna is connected

2. Make sure the AP100 blue radio chip is pressed in fully and tight

3. Make sure the AP100 is in learn search mode

4. Make sure the sensor battery is tightly plugged on

5. Press the learn button a few times. The green LED should turn On/Off.

6. Reset the sensor

7. Reset the AP100 - Caution this will completely clear the AP100 and all sensors

AP100 learned two Sensors as the same

Sensor Number. Example: Learned

Sensor1 and Sensor2 both as Sensor1

1. Program the shared Sensor number ACTIVE.

2. Delete the shared Sensor number.

3. Reset the Sensors and relearn.

AP100 does not see Sensor detect

1. Make sure the Sensor has been programmed ACTIVE

2. Mount the AP100 antenna as high as possible and in a clear line of sight to the sensor.

Tip: From your hands & knees, look from the ground to the antenna. The full antenna

should be visible and not blocked from each sensor.

Relay is on and AP100 LCD shows

SENSOR FAIL

1. AP100 is not communicating with the sensor

2. Make sure the antenna connections are tight and the blue radio chip is tight.

3. Mount the AP100 antenna higher to get better communication

4. Make sure the sensor is flush with the roadway and not below the road surface.

All relays are on and the AP100 LCD

shows AP FAIL

1. AP100 is not communicating with any of the sensors.

2. Make sure the AP100 blue radio chip is pressed in fully and tight and all antenna

connections are tight.

3. Mount the AP100 antenna higher and in a clear line of sight to each sensor

4. Move the sensors closer to make sure they communicate with the AP100

Sensor detects and shows on LCD but

does not activate relay

1. Make sure that Sensor is programmed to a relay.

2. Make sure the relay is programmed to a function other than NONE. None is the

default.

Troubleshooting

Summary of Contents for WVD100

Page 24: ...www AccessOneTechnologies com...