8

Packing

Clamp Bolt

Support Tube

and Flange

(min. bore

42.0 mm dia.)

Thermal

Insulation

Fixing

Flange

Furnace

Wall

150mm (5.91 in.)

minimum

Min. 42.0 mm dia.

Thermal Insulation

Furnace

Wall

Soft Ceramic Fibre

Support Tube

10

°

min.

Thermal

Insulation

Support

Tube

Furnace

Wall

Soft

Ceramic

Fibre

…3

INSTALLATION

3.3

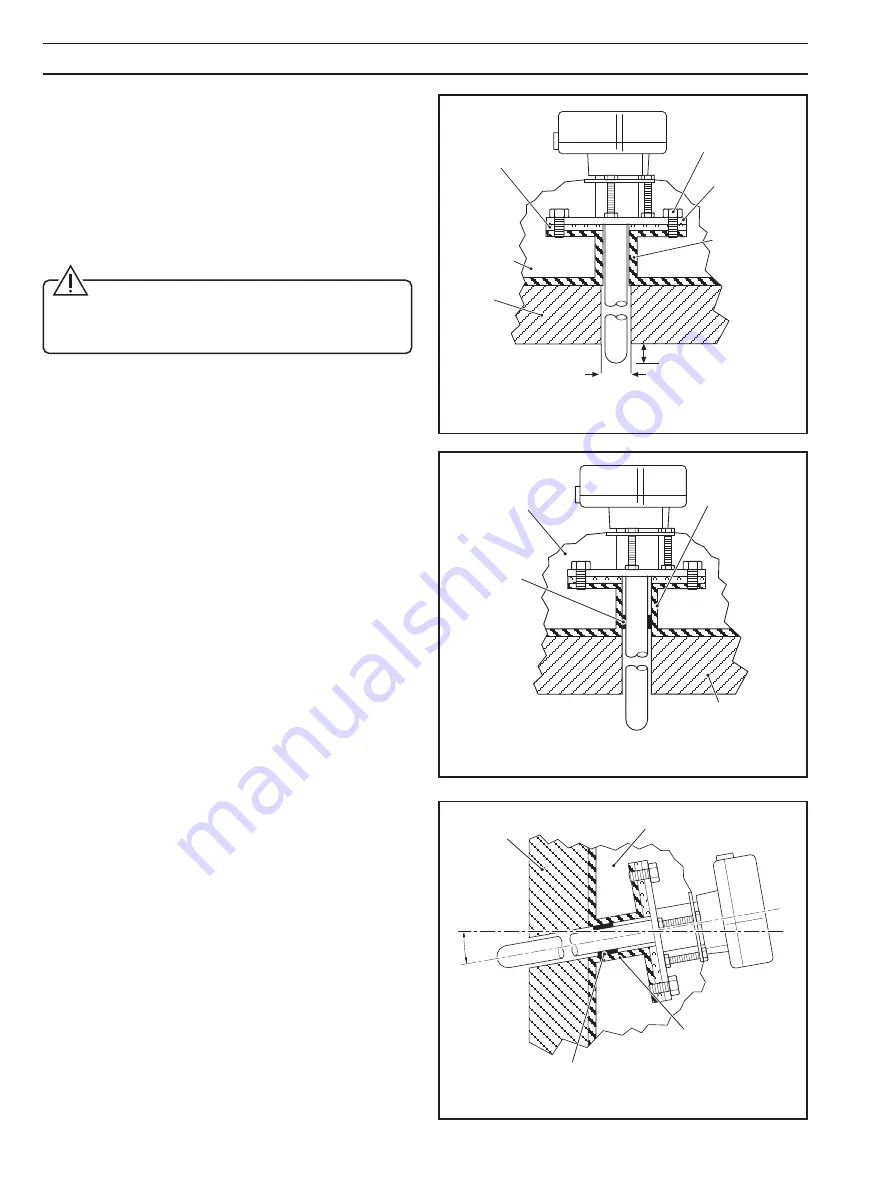

Mounting – Figs. 3.7 to 3.9

The probe may be fitted horizontally or, preferably, vertically

for prolonged high temperature operation.

Mount the probe through the furnace wall using the preferred

method shown in Fig. 3.7. Ensure that a sufficiently large hole

is provided through the mounting (min. bore 42mm diameter)

to avoid damage to the probe during insertion or use.

Drill the fixing flange to suit the local fixing requirements before

assembling the probe – see Section 2.3

.

Caution

. To prevent furnace gas from

contaminating the reference air, always ensure that the

clamp ring, fixing flange and sealing ring are fitted to the

probe as described in Section 2.3.

In applications such as high temperature incinerators, fluid

bed boilers, and ore roasters, where the level of water vapour

in the waste gases to be measured can be extremely high, it is

important that the mounting flange of the probe, including any

stand-off which may be used, is thermally insulated to

minimize condensation within the probe – see Fig. 3.7.

Condensation within the probe sheath, particularly in outdoor

installations, can be sufficient to allow water to come into

contact with the hot ceramic (zirconia) tube leading to thermal

shock and failure of the sensor. This problem is most likely to

occur on such installations where the plant is shut-down

regularly over the week-end. Additionally, take care to protect

the head of the probe from the elements in out-door

installations.

Raising the temperature of the probe as rapidly as possible will

assist in reducing the level of condensation. This is not

possible on some processes where the plant temperature is

gradually raised to the normal operating level. The

temperature rise at the head of the probe can be assisted by

having a large clearance hole in the refractory allowing hot

gases to get up to the mounting flange/stand-off – see Fig. 3.8.

The problems described above are more likely to occur on

horizontal installations. Where it is not possible to mount the

probe in the vertical position, install the probe with a slope of at

least 10 to 15

°

downwards from the head of the probe –

see Fig. 3.9.

Fig. 3.7 Probe Mounting (standard configuration)

Fig. 3.8 Probe Mounting (for improved probe heating)

Fig. 3.9 Probe Mounting (inclined configuration)