11

s

a

G

t

s

e

T

f

o

t

l

u

s

e

R

k

c

e

h

C

f

o

e

s

u

a

C

e

l

b

i

s

s

o

P

n

o

i

t

a

r

e

p

O

n

o

i

t

c

n

u

f

l

a

M

n

o

i

t

c

A

.

t

c

e

r

r

o

C

.

e

n

o

N

.

t

c

e

r

r

o

c

n

I

y

l

p

p

u

s

r

i

a

e

c

n

e

r

e

f

e

R

O

h

g

i

h

(

e

r

u

li

a

f

2

.

)

g

n

i

d

a

e

r

e

b

o

r

p

k

c

e

h

C

.

y

l

p

p

u

s

r

i

a

e

c

n

e

r

e

f

e

r

t

i

n

u

s

c

i

n

o

r

t

c

e

l

e

y

t

l

u

a

F

.

r

o

t

a

c

i

d

n

i

r

o

f

o

n

o

i

t

a

r

e

p

o

k

c

e

h

C

.

d

e

n

r

e

c

n

o

c

s

t

i

n

u

e

b

u

t

a

i

n

o

c

r

i

z

n

i

k

a

e

L

n

e

k

o

r

b

r

o

e

b

o

r

p

n

i

h

t

i

w

O

h

g

i

h

(

e

b

u

t

a

i

n

o

c

r

i

z

2

.

)

g

n

i

d

a

e

r

n

o

i

t

a

r

e

p

o

e

r

a

p

m

o

C

O

r

e

h

t

o

n

a

h

t

i

w

2

f

i

e

c

a

l

p

e

R

.

e

b

o

r

p

.

y

r

a

s

s

e

c

e

n

g

n

i

t

f

i

r

d

r

o

o

r

e

Z

o

n

h

t

i

w

s

g

n

i

d

a

e

r

t

s

e

t

o

t

e

s

n

o

p

s

e

r

.

s

a

g

.

e

b

o

r

p

t

i

u

c

r

i

c

n

e

p

O

y

t

i

u

n

i

t

n

o

c

r

o

f

k

c

e

h

C

.

w

o

l

e

b

e

e

s

–

t

i

n

u

s

c

i

n

o

r

t

c

e

l

e

y

t

l

u

a

F

r

o

r

o

t

a

c

i

d

n

i

.

s

n

o

i

t

c

e

n

n

o

c

f

o

n

o

i

t

a

r

e

p

o

k

c

e

h

C

.

d

e

n

r

e

c

n

o

c

s

t

i

n

u

7

FAULT FINDING

Warning.

The probe operates at high

temperatures. Take all necessary precautions to avoid

injury through burns.

During its working life under normal recommended conditions

the probe output remains accurate and without drift. Probe

malfunctions can result from a fault in the probe or from

incorrect operating conditions.

The testing of a suspect probe can only be carried out

satisfactorily in its working position or in a furnace controlled

within the normal probe operating temperature range.

If a probe failure is suspected, first perform a test gas check as

described in the following sections.

7.1

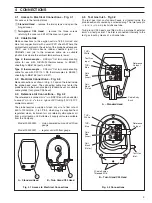

In Situ Checking Using a Test Gas

Introduce a test gas of known concentration around the outer

electrode in the space between the filter washer, at the bottom

of the sheath, and the wadding around the lower end of the

probe – see Fig. 2.1. Four vent holes prevent the gas from

being trapped in the upper part of the sheath.

7.1.1

Standard Head

a) Gain access to the interior of the probe head by

unscrewing the lid fixing screws – see Section 4.1,

Access

to Electrical Connections

.

b) Remove the screwed plug from the test gas connector –

see Fig. 4.2A.

c) Fit

1

/

4

in i.d. x

3

/

8

in o.d. plastic or similar tubing and supply a

test gas of known oxygen concentration to the probe at a

steady flow rate of 800 to 1000ml/min (1.7 to 2.1ft

3

/hr).

Allow at least 5 minutes for the system to stabilize before

making a measurement.

d) Check that the oxygen concentration measured by the

probe system indicator or recorder, compares with the

specification for the test gas used.

e) Disconnect the test gas and ensure that the screwed plug

is replaced in the test gas connector. Failure to do this may

result in serious measurement errors due to the entry of air

into the probe.

f)

Proceed to Table 7.1.

7.1.2

Twin Gland C95 Head

a) Remove the blanking screw in the external test gas inlet

and connect a gas supply of known oxygen concentration

– see Fig. 4.2. If a permanent test gas connection is used,

switch on the gas supply.

b) At a steady flow rate of 800 to 1000ml/min (1.7 to 2.1ft

3

/hr),

allow at least 5 minutes for the system to stabilize before

making a measurement.

c) Check that the oxygen concentration measured by the

probe system indicator or recorder, compares with the

specification for the test gas used.

d) If the test gas supply is not connected permanently to the

probe head, disconnect the supply from the external test

gas inlet and replace the blanking screw.

e) Proceed to Table 7.1.

7.2

Comparison with Another O

2

Probe

The probe may be checked by comparison with another of

known reliability, either by replacing the suspect probe with the

known probe or by mounting the known probe in close

proximity and monitoring both probes continuously for a short

period.

7.3

Returning the Probe to the Factory for

Checking

If it is not possible to carry out the above tests on site and

failure or malfunction is suspected, the probe may be returned

to the Company for checking, in which case the probe must be

carefully dismantled and repacked in its original packing to

ensure safe carriage.

7.4

Continuity Check

Connect a 100k

Ω

resistor across the probe output. If the

output drops to near zero millivolts and then drifts when the

resistance is removed, this indicates that the probe may be

open circuit or have a high impedance.

Table 7.1 Fault Finding