1MRS750500-MUM

Feeder, Machine and Transformer Terminals

Operator’s Manual

RE_ 54_

5

1.

About this manual

1.1.

Copyrights

The information in this document is subject to change without notice and should not

be construed as a commitment by ABB Oy. ABB Oy assumes no responsibility for

any errors that may appear in this document.

In no event shall ABB Oy be liable for direct, indirect, special, incidental or

consequential damages of any nature or kind arising from the use of this document,

nor shall ABB Oy be liable for incidental or consequential damages arising from

use of any software or hardware described in this document.

This document and parts thereof must not be reproduced or copied without written

permission from ABB Oy, and the contents thereof must not be imparted to a third

party nor used for any unauthorized purpose.

The software or hardware described in this document is furnished under a license

and may be used, copied, or disclosed only in accordance with the terms of such

license.

Copyright © 2005 ABB Oy

All rights reserved.

1.2.

Trademarks

ABB is a registered trademark of ABB Group.

All other brand or product names mentioned in this document may be trademarks or

registered trademarks of their respective holders.

1.3.

Guarantee

Please inquire about the terms of guarantee from your nearest ABB representative.

1.4.

General

This document, Operator’s Manual for RE_ 54_, instructs how to use the graphic

HMI of the REF 54_, REM 54_ and RET 54_ terminals.

Please note that the HMI views in the pictures of this manual are exemplary.

1.5.

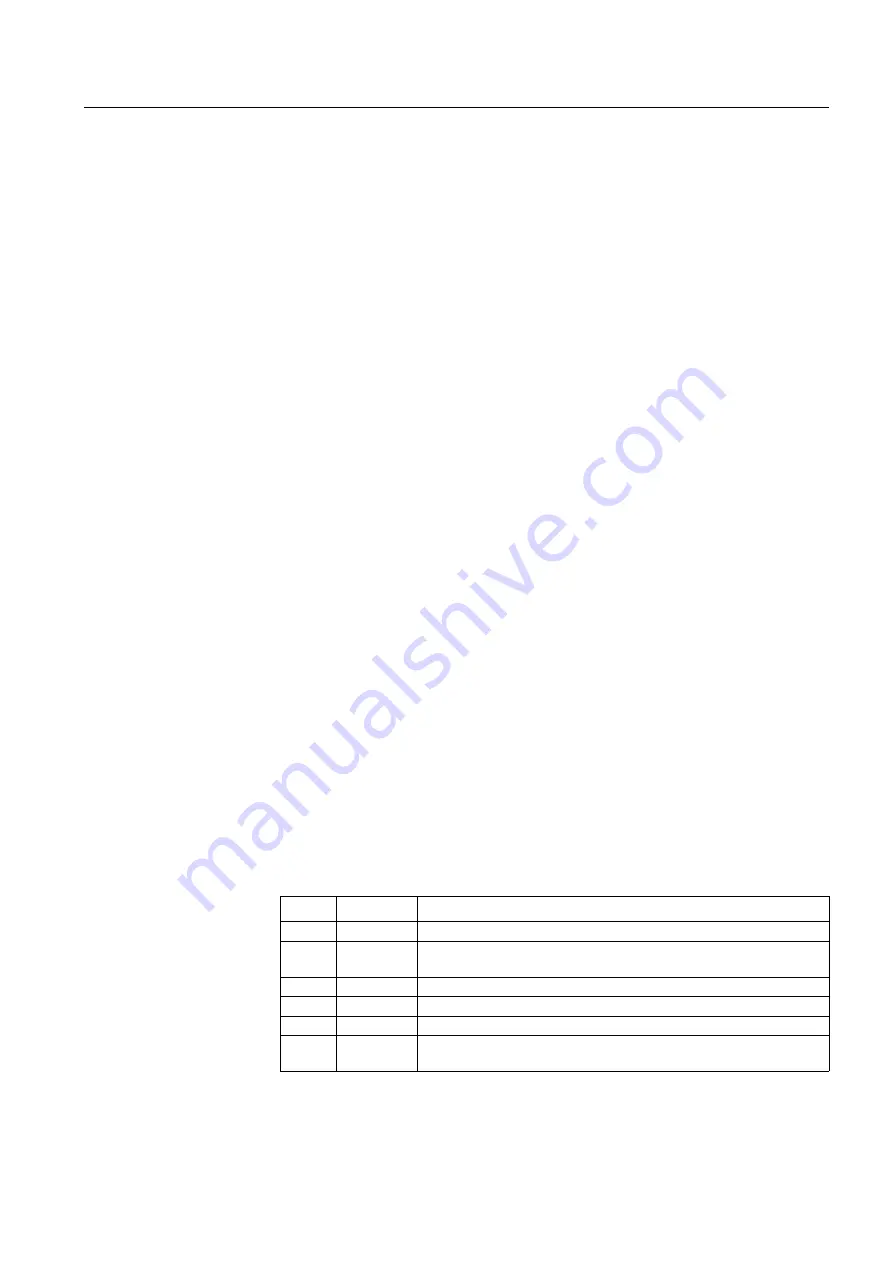

Document revisions

Version Date

History

G

3.5.2002

Section “IRF test” added

H

4.6.2003

Section “Emergency stop function” added

Text added to sections “Self supervision (IRF)” and “Main window”

H

25.3.2004 Layout changed

H

25.5.2004 Layout changed

K

15.8.2004 Text and pictures updated throughout the manual

M

20.01.2005 RET 54_ Transformer terminal added to the manual

Pictures updated