LMT10 0 A N D LMT 20 0 |

M AG N E TOS T R I C T I V E L E V EL T R A N SM I T T ER S | FF O I/L M T 10 0/ 2 0 0/FF - EN R E V. A

65

9 Fieldbus installation considerations

Important Further information on FOUNDATION Fieldbus can

be found from the Fieldbus Foundation organization website

www fieldbus org

Feature overview

The LMT100/200 Foundation Fieldbus are compliant to the

communication Protocol FOUNDATION™ Fieldbus specification

ITK6 3 0

FF Manufacturer ID = 0x000320 (ABB)

FF Device type ID = 0x0096 (LMT Magnetostrictive)

Device Type = Link Master

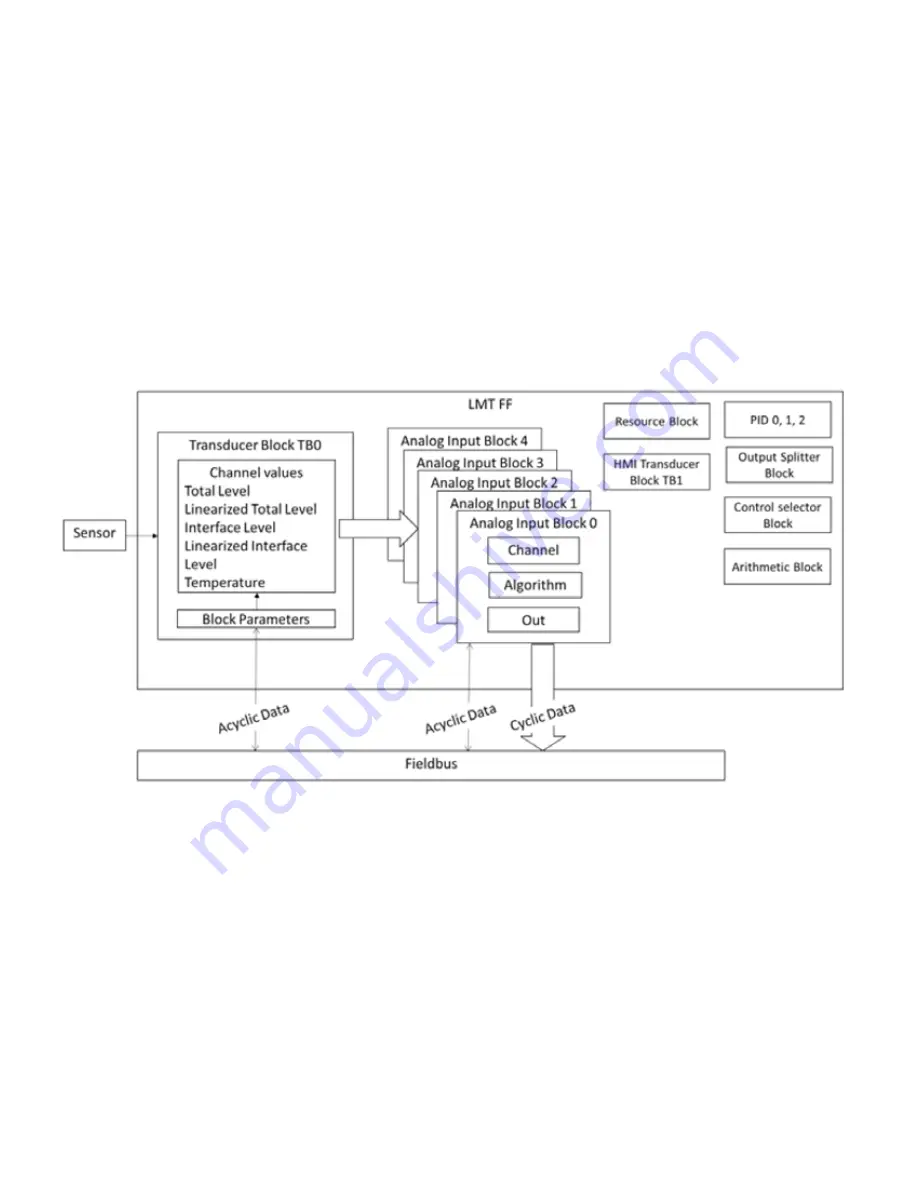

LMT100/200 FF are implementing the following Blocks:

– 1 Standard Resource Block

– 5 Analog Input Function Blocks

– 3 PID Function Block

– 1 Arithmetic Function Block

– 1 Control Selector Function Block

– 1 Transducer Block with Linearization Table

– 1 HMI Transducer Block

Registration details

All the Registration details are available from the Fieldbus

Foundation webpage

Fieldbus device structure

The Foundation Fieldbus devices can be divided into two parts

under the point of view of technical competence who must take

care of its configuration and use

– The Device Application Process (DAP) is device specific and

stays with the device wherever it is used

– The Control Application Process (CAP) is configured for the

specific plant location and may be spread over multiple

devices

Communication between the DAP and CAP takes place using

channels Each I/O function block in the CAP has exclusive use

of exactly one channel A channel may be bi-directional and it

may have multiple values

Device Application Process (DAP)

The DAP is used primarily by the instrumentation technician or

maintenance personnel for configuring I/O when the

instrument is going to be installed in the plant and/or during

maintenance operations and for this reason mainly focused on

the Resource Block and Transducer Blocks of the device