Start-up and operation 19

Units with functional grounding (negative as standard, positive as an F283): Force grounding

from parameter 210.01. Verify the grounding current from parameter 210.14.

If faults or warnings occur, refer to the

Firmware manual

.

Set the grounding mode to “Automated” from parameter 210.01 and configure the grounding to suit the

local requirements.

Refer to the

Firmware manual

.

Set the grid code according to the local requirements.

Refer to the

Firmware manual

.

Adjust parameter 174.01 and 174.02 “M1-2 connected DC inputs” according to the actual

input connection configuration

Verify that no faults or warnings are active. If faults or warnings occur, refer to the

Firmware manual

.

Turn the Start/Stop switch to “start”, set parameter 189.01 to “Enable”, and start the inverter.

A normal starting procedure:

After the start command, the inverter goes from the “Initialize” to the “Disconnected” state (refer to

parameter 173.02). If there is sufficient DC voltage, and the ground impedance is within range, the

inverter goes to the “Connecting” state after the delay set in parameter 213.10.

In this state inverter charges the DC capacitors from the AC output and synchronizes to the grid. The DC

contactor closes. The inverter goes to the MPPT state and starts to produce active power to the AC

output. When there is not enough DC voltage or power available, the inverter goes to the “Disconnecting”

state after the delay set in parameter 213.13.

Make sure that the inverter operates properly from the following actual value parameters:

• 101.01 DC Voltage

• 101.12 Power

• 174.31 to 174.94 where the active input parameters depend on the DC input options (+G417).

The DC voltage should decrease from the open circuit voltage and the active power should match the

line current and the AC voltage.

Set up fieldbus control

Connect the external communications, for example, for the data logger, plant controller or SCADA

system. Obey the safety rules as instructed in the PVS980-58 manuals when doing this.

Configure network interface to match with the local network (refer to the

Firmware manual

).

Set the fieldbus parameters according to the external controller.

Refer to the

Firmware manual

and the fieldbus adapter module manual.

Make sure that the inverter can be seen from the external controller.

Verify that the plant controller receives the correct values from the inverter and sends the correct values

to the inverter.

Register the inverter

Fill in a commissioning report to register the inverter.

The report is on the InstalledBase web page:

https://businessapps.abb.com/sites/DrivesIB4/Pages/default.aspx

If you cannot access the InstalledBase, submit a Membership Request on the Installed Base main page.

Note that InstalledBase is only for ABB internal or ABB partner use.

It is required to attach the parameter lists and back-up files of the inverter. to the report.

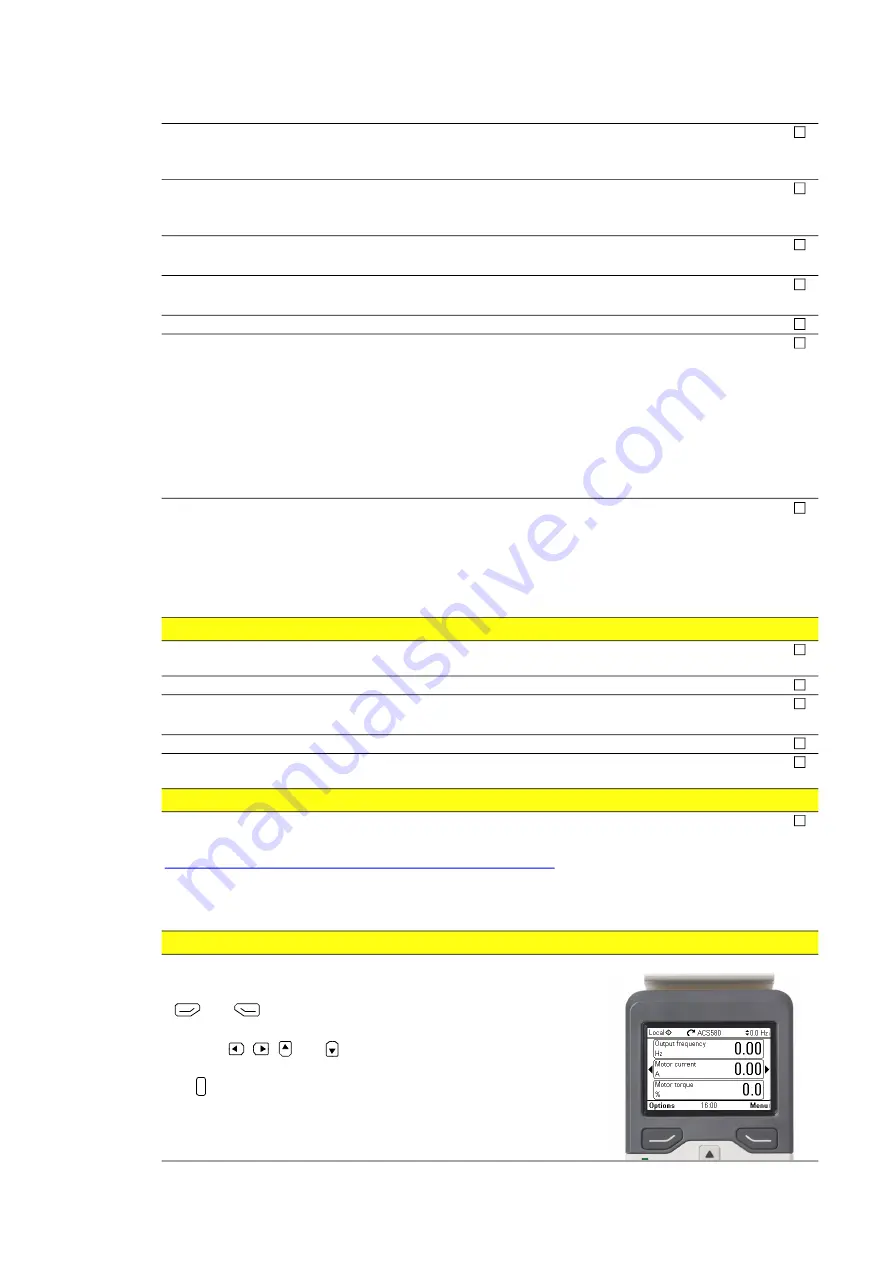

Hints on using the assistant control panel

The two commands at the bottom of the display (in the figure on the right,

Options and Menu), show the functions of the two softkeys

and

located below the display.

The commands assigned to the softkeys vary depending on the context.

Use keys , , and to move the cursor and/or change values

depending on the active view.

Key shows a context-sensitive help page.

For more information, refer to

ACS-AP-x assistant control panels user’s

manual

(3AUA0000085685 [English]).

?

Summary of Contents for Fimer PVS980-58-1818kVA-I

Page 1: ...Central inverter PVS980 58 From 1818 to 2091 kVA Commissioning and maintenance manual ...

Page 4: ...2 ...

Page 14: ...12 Safety instructions ...

Page 18: ...16 Introduction to the manual ...

Page 28: ...26 Electrical commissioning ...

Page 60: ...58 Maintenance ...