ACH550-UH User’s Manual

97

3006

MOT THERM TIME

256…9999 s

1

1050 s

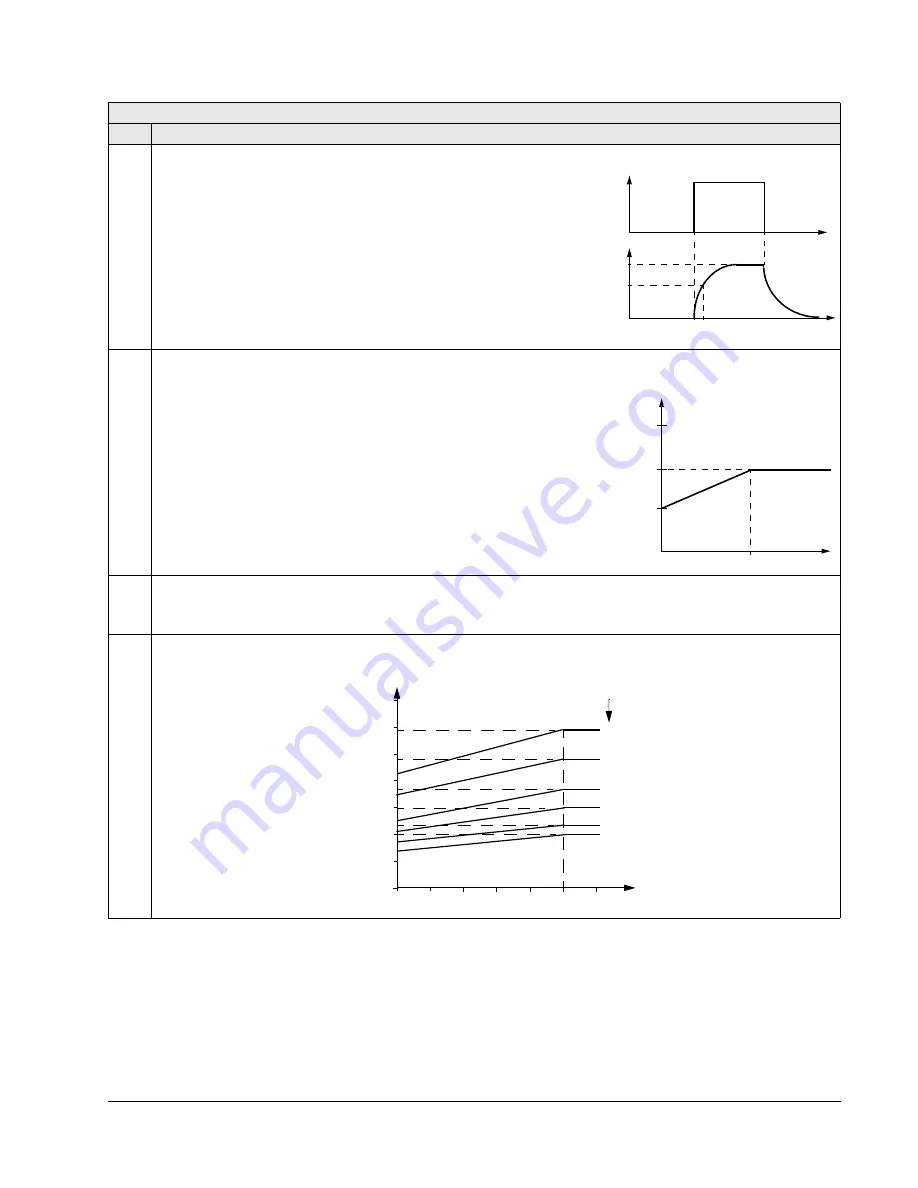

Sets the motor thermal time constant for the motor temperature

model.

• This is the time required for the motor to reach 63% of the final

temperature with steady load.

• For thermal protection according to UL requirements for NEMA

class motors, use the rule of thumb:

MOTOR

THERM

TIME

equals

35 times t6, where t6 (in seconds) is specified by the motor

manufacturer as the time that the motor can safely operate at

six times its rated current.

• The thermal time for a Class 10 trip curve is 350 s, for a Class

20 trip curve 700 s, and for a Class 30 trip curve 1050 s.

3007

MOT LOAD CURVE

50…150%

1

100%

Sets the maximum allowable operating load of the motor.

• When set to 100%, the maximum allowable load is equal to the

value of Start-up Data parameter 9906

MOTOR

NOM

CURRENT

.

• Adjust the load curve level if the ambient temperature differs from

nominal.

3008

ZERO SPEED LOAD

25…150%

1

70%

Sets the maximum allowable current at zero speed.

• Value is relative to 9906

MOTOR

NOM

CURR

.

3009

BREAK POINT FREQ

1…250

Hz

1

35

Hz

Sets the break point frequency for the motor load curve.

Example:

Thermal protection trip

times when parameters 3006

MOT

THERM

TIME

, 3007

MOT

LOAD

CURVE

and 3008

ZERO

SPEED

LOAD

have default

values.

Group 30: Fault Functions

Code Description Range

Resolution

Default

S

Temp. Rise

100%

63%

t

t

}

P 3006

Motor load

Frequency

Output current (%) relative

to 9906

MOTOR

NOM

CURR

150

100

50

P 3007

P 3008

P 3009

60 s

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0

0.2

0.4

0.8

1.0

1.2

I

O

/I

N

f

O

/f

BRK

90 s

300 s

600 s

0.6

180 s

A

∞

I

O

= Output current

I

N

= Nominal motor current

f

O

= Output frequency

f

BRK

= Break point frequency

A = Trip time