5

40

18

80

80

82

99

12

102,

104,

106

100

84

88

90

92, 94

38

36

68

69

70

72

74

60

58

58

14

56

62

64

28

42

26

30

96

100

55

76

16, 20,

22, 24, 25

98

102, 104, 106

40

38

36

60

58

15

66

54

67

14

56

62

64

28

42

26

30

96

100

16, 20,

22, 24, 25

98

102, 104, 106

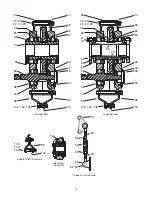

Straight Bore

Taper Bushed

Torque-Arm Assembly

Backstop

Assembly

Adapter Plate Assembly