2

Before installation, read this notice carefully and keep

it at disposal of people in charge of installation, main-

tenance and operation.

Read this first

Safety

WARNING!

Wait 5 min. after isolating supply before

handling. As an additional precaution before commenc-

ing work, short-circuit the capacitor terminals with a

piece of insulated cable to confirm discharge.

For a safe use of CLMD capacitor units, please ensure

• Installation and maintenance are undertaken only by

authorized and qualified personnel, in accordance

with current local regulations;

• Isolate the equipment from the supply before at-

tempting to gain access.

Inspection on reception

Unpack the CLMD and check that:

• data on the label correspond to those of your pur-

chase order and local regulations;

• the CLMD is not damaged.

Any loss or damage should be notified immediately

to your closest ABB agent.

Storage

Indoor, in dry, dust free and non-corrosive environ-

ments, protected from vibrations or shocks. Storage

temperature: minimum: -40°C/-40°F, maximum:

75°C/167°F.

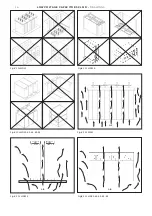

Transportation and handling (Fig. #1)

In case severe conditions of transportation are ex-

pected, we recommend that the panel including

CLMD units be positioned in such a way that CLMD fixa-

tion points are at the bottom. For CLMD33/33S, more

positions are allowed.

WARNING!

Failure to respect the installation rules may

lead to premature failure, other material damage to in-

stallations or bodily injury.

Installation

Applicable standards

IEC 60831 Parts 1 and 2. Current local regulations.

Protection

CLMD13, 43, 53, 63 and 83: IP42

CLMD45, 65 and 85: IP54

CLMD33 / 33S: IP40

See capacitor nameplate for IP degree.

Installation and use

Indoor installation on firm foundation or fixed on a

rigid plate/frame in well-ventilated situations where

the air temperature around the capacitor does not ex-

ceed 35°C/95°F over one year, 45°C/113°F over 24 hours

and 55°C/131°F (according to IEC 60831 Parts 1 and 2

for a -25/D temperature category product).

CLMD13, 43, 53, 63 and 83 also exist in outdoor execu-

tion. The temperature class is then -40/D according to

IEC60831. See nameplate for specification. Exposure

to sun may overheat capacitors. Special care must be

taken.

WARNING!

The ambient temperature for capacitors in-

side a cubicle is the temperature around the capacitors

and not around the cubicle.

WARNING!

Like other standard capacitor units, CLMD

discharge devices are not suitable for use with rapid

switching rates (minimum off time: 40“). Additional

external resistors are not a solution for such cases.

Only specially designed capacitors must be used in

such applications.

Vertical and horizontal mounting

The CLMD capacitors must be fixed in such a way as to

ensure a natural airflow from bottom to top.

Minimum free space between units:

• CLMD13: 20mm

• CLMD33 / 33S: 20 mm (25mm for units

≥

30 kvar)

• CLMD43-45, 53, 63-65 and 83-85: 50mm

In case of vertical mounting, use a punched mounting

plate or support bars to allow free airflow between the

capacitors (Fig. #2). Do not mount upside down. (Fig.

#3)

In case of horizontal mounting, install so that the natu-

ral airflow goes between the units (Fig. #4). Do not

mount so that the natural airflow is blocked (Fig. #5).

Installation in a cubicle

WARNING!

Guidelines only apply if the following limits

are respected:

• Maximum room temperature: 40°C (1 hour).

• Average maximum room temperature over 24 hours:

35°C.

• Average maximum room temperature over 1 year:

25°C.

When the capacitors are installed in a cubicle the com-

ponents should be placed in such a way as to optimize

the cooling. Do preferably place devices with high heat

dissipation above the capacitors to avoid overheating

them. When reactors are used they should be placed in

such a way that they do not radiate heat directly on the

capacitors. A thermal barrier is recommended. Reac-

tors do in general dissipate much more heat, so their

thermal impact through convection must also be taken

into account.

1. Natural air circulation

The difference in height between air inlet and air outlet

should be large enough to improve the air circula-

tion. The airflow should be channeled in such a way as

to well cool the hottest spots in the cubicle. Air should

flow from the bottom to the top of the cubicle. The

cross-section of the top air outlet should be at least

equal to 1.2 times the cross-section of the bottom air

inlet.

LOW VOLTAG E C A PACITOR S CLM D -

EN G L I SH

en