10

…3

MECHANICAL INSTALLATION

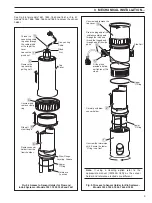

Reference

Junction

Temperature

Compensator

(Blue Ring)

Reference

Electrode

(Black Ring)

Measuring

Electrode

(Red Ring)

ASEA

BROWN BOVERI

K

e

REFERENCE ELECTRODE

K

e

n

t -T

a

y

lo

r

ASEA

BROWN BOVERI

K

e

n

t -

ASEA

BROWN BOVERI

Ensure 'O' ring

is fitted

Insert into

Sensor Holder

Tighten fully

Repeat steps

1

,

2

and

3

for

each electrode

3

4

1

2

3.3.2

Fitting the Reference Electrode – Figs. 3.8

a) Remove the reference electrode 1730-000 from its box; the

box should also contain a bottle of KCl solution (slurry).

Caution.

Wear eye protection when filling the

reference electrode with KCl solution (slurry).

b) Shake the bottle of KCl solution well to ensure it is mixed

thoroughly so that the solids are freely dispersed in the

solution.

c) Slowly fill the reference chamber with solution through the

filling hole (see Fig. 3.8a) . Fill in small quantities and shake the

bottle frequently to keep the KCL in suspension (the contents

of one bottle should fill the reference chamber and allow for

displacement when the reference electrode is fitted).

d) Wipe dry the area around the filling hole.

e) Fit the reference electrode

IMMEDIATELY

ensuring that the

‘O’ ring is fitted over the electrode – see Fig. 3.9.

Note.

To ensure correct fitting of the electrode, it may

be necessary to clear a path through the slurry in the

chamber. Do this using the reference electrode gently

in an up-and-down motion to clear a path.

f)

When a path has been cleared, position the electrode and

screw down firmly to ensure a good seal.

g) Shake the sensor holder to ensure that the KCl slurry reaches

the bottom of the chamber.

h) Invert the sensor holder and remove the reference

junction (Fig. 3.8). Check the level of the slurry; top up if

necessary. Refit reference junction.

There are two reference junctions available:

•

1360 180 Small Reference Junction: supplied with all sealed

reference electrodes. The junction is suitable for use in

general applications where the loss of KCl is minimised and

where the pressure can reach 10bar (145 psi).

•

1360 190 Large Reference Junction: supplied with reservoir-

fed reference systems to give a reproducible KCl flow rate.

The junction can be used on sealed reference system on low

conductivity applications to reduce instability problems or on

sample where high level of solids that cause rapid blockage of

the small junction. The large junction must be used only on

flow systems or dip systems operating at atmospheric

pressure.

3.3.3

Fitting the Measuring Electrode, and

the Temperature Compensator 1750-000 (if required)

– Figs. 3.9 and 3.10

Note.

If a temperature compensator is not fitted,

ensure the blanking plug (Fig. 3.10) is fitted (Redox).

a) Remove the temperature compensator (1750-000) and the

measuring electrode from their packaging. If the measuring

electrode is a glass electrode, carefully remove and discard

protective teat.

b) Fit the electrodes as shown in Fig. 3.9.

Fig. 3.8 Sealed Types

(Electrodes and Temperature

Compensator Omitted for Clarity)

Fig. 3.9 Fitting the Electrodes into the Sensor Holder