6

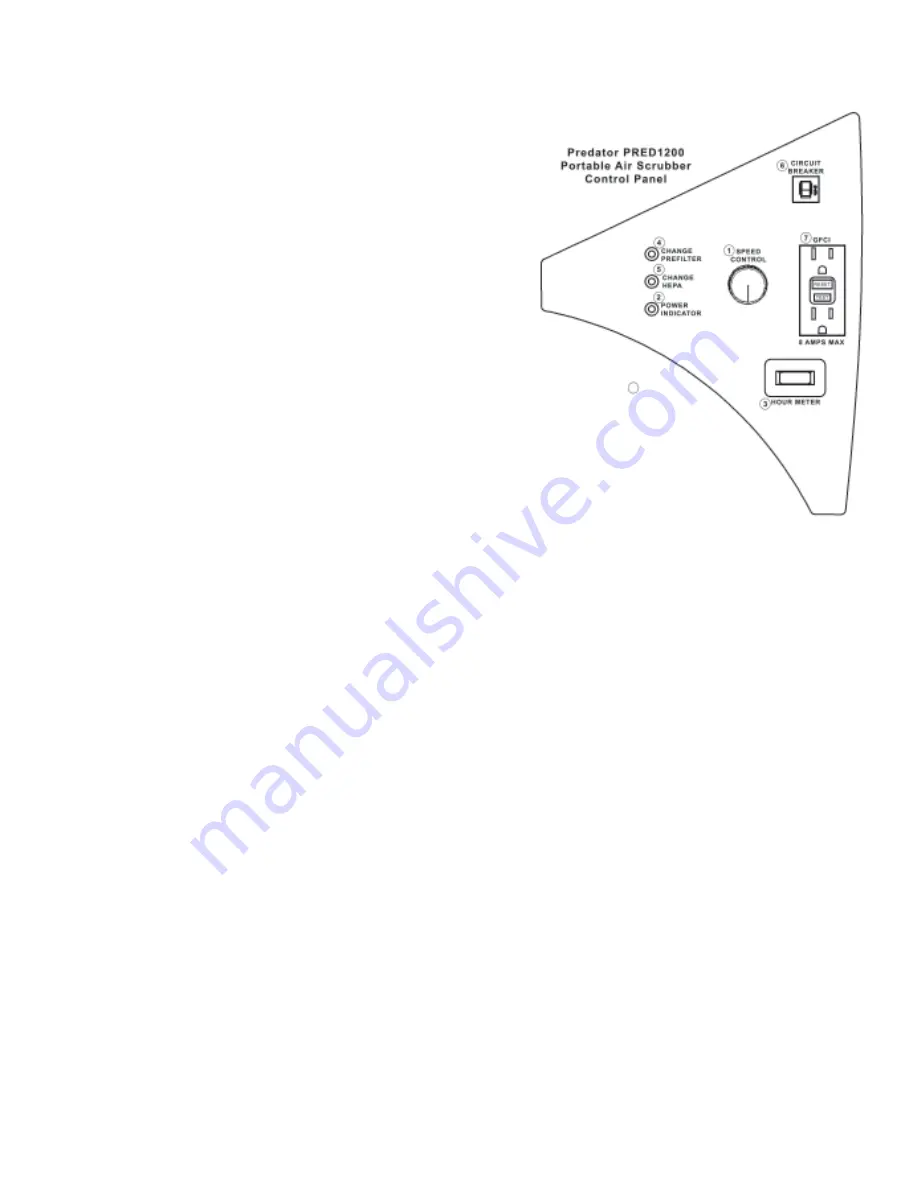

PRED1200 CONTROL PANEL

1. Speed Control Switch

- Serves as the power switch

and provides a variable adjustment to the speed of the

motorized impeller.

2. Power Indicator

- Green light that indicates speed

control switch is “ON” and system is connected to

power source.

3. Hour Meter

- Provides a count of the total operating

hours.

4. Filter Change Indicator - Pre-filters

– Red light that

indicates excessive restriction on air intake or loading

of the pre-filter(s) and that filter change procedures

should be followed.

5. Filter Change Indicator - HEPA

- Red light that

indicates excessive restriction on air exhaust or loading

of the HEPA filter and that filter change procedures

should be followed.

6. Circuit Breaker -

12 amp circuit breaker that provides

protection for the unit’s electrical components.

7. GFCI Receptacle

- Electrical safety device that will

trip and stop the flow of electricity if leakage of current

is detected from the unit or an electrical device plugged

into the GFCI receptacle. The PRED1200 can supply a

total of 8 amps of electrical power for additional

equipment that is connected to the GFCI receptacle.

Do not exceed this 8 amp limit.

Note

: If the equipment connected to the GFCI receptacle draws more than a total of 8 amps, the circuit

breaker on the control panel and/or the building breaker will trip. This condition can be remedied only by

reducing the total amperage draw.

BEFORE OPERATING THE UNIT, NOTE THE FOLLOWING

:

Inspect and tighten any HEPA filter retaining nuts that may have loosened during transportation. Inspect the filters

for any material or structural damage prior to use and replace any damaged filters before operating the unit.

When removing any filters prior to operation, always put them back in place with airflow indicator on filter housing

oriented in the proper direction (if applicable).

As with any air filtration system, external airflow losses not attributable to the air filtration unit will reduce the

airflow of the system. The following recommendations can minimize airflow losses created by external static

resistance.

1. Always use the minimum length of ducting possible with the fewest possible number of turns and bends.

2. Rigid metal ducting creates less turbulence and consequently less airflow loss than flexible ducting.

Regardless of the type of ducting used, rigid, “sweep-type’, radiused connections should be used for all

turns and bends.

3. If flexible ducting is used, it must be kept as taut as possible to avoid flattening.

LOCATION OF THE UNITS AND MODES OF OPERATION

1.

Negative Pressure

- used to help ensure that airborne contaminants do not escape from a contained

area, by maintaining negative (lower) air pressure within that area compared to adjacent areas. This is

generally accomplished by placing the unit inside the containment area and exhausting filtered air from

the unit out of the area. The filtered air must be exhausted outside of the containment area, either