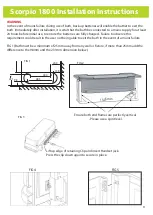

Panel Fixing

The bath shell comes complete with the outer upper panels fitted. These should fit outside the inner

lower panels and should not touch them. Note: if the upper and lower panels touch, marking will occur.

Adjustment is possible on the bayonet clip if required.

Inner Panel Fitting

Offer the corner inner end panels (right and left) up to the bath and secure

using the M4 x 12mm white plastic topped machine screws

supplied (Fig. a) Screw through holes in panels and into

the rivnuts positioned in the frame uprights.

Use the white plastic binding fixings (Fig. b) to secue the inner panels together.

There will be one half of the screw assembly already bonded in each hole. Use

a quantity of 2 to connect the right corner inner panel to the left corner inner panel.

Use a quantity of 2 to connect the inner centre panel to the right and left corner

panels either side.

Sliding Panels

The Bath will be delivered with the sliding bracket metal-work

assembled (Fig. c)

This assembly will be fixed to the bath using 2

M8 Hex bolts through the slots and into the threaded

holes in the bath support bars.

It is important that the plate is square to the support

bars as it is crucial that the sliding brackets are

parallel to the sliding panel. If not the

panel will not rise and

fall as intended.

Scorpio 1800

Customer Instruction Certificate

Testing the Bath

WARNING!

The system batteries must be charged for 24 hours prior to using the bath. You may test the

bath to ensure it is working correctly.

Ensure that hands and objects are kept away from the underside and topside when

operating the bath.

Ensure the floor area around the bath is kept free from excess water to avoid

persons slipping.

Do not allow unauthorised persons to operate the bathing system.

This bath moves. Ensure there are no objects or persons that can become trapped or injured

while the bath raises or lowers.

BATH OPERATION

To operate the unit:

The handset control buttons are completely safe to use with wet hands, the up/down

buttons operate independently on a ‘depress-to-run’ basis, in that movement will stop if the

button is released.

Make sure the bath is in the fully lowered position using the Handset Bath DOWN button.

Check the pop up waste is in the fully closed position.

Fill the bath approximately half full with water. Check the water temperature is within safe

bathing limits 40˚-43˚.

Raise the bath using the Bath UP button on the handset.

Empty the water whilst the bath is in the up position as this will help with the draining

of the bath.

Fully lower the bath using the Bath DOWN button on the handset.

Clean the bath as per the cleaning instruction.

Where a safety lap belt is supplied this must be used for the safety of the bather.

WARNING! If this unit is to be utilised by many different bathers, we would strongly

recommend that it is cleaned regularly with a medical disinfectant as well as following

a strict cleaning routine.

WARNING

In the event of mains failure during use of the bath, back-up batteries will enable the

bather to exit the bath. Do not carry on using until mains power is restored.

13