8

Control systEM opEratIon

hEatInG ElEMEnt opEratIon

Progressive Sequencing:

Elements are energized and de-energized

according to adjustable (1 to 20°F) Differential set points for each element.

Element Rotation - first element on is rotated with each successive call

for heat. First On/First Off - the first heating element energized at the

beginning of a heating cycle is the first element de-energized at the

end of the heating cycle. Successive heating cycles would progress as

follows on a model equipped with 3 heating elements:

• First heating cycle: Elements come on [1, 2, 3] and cycle off [1, 2, 3].

• Second heating cycle: Elements come on [2, 3, 1] and cycle off [2, 3, 1].

• Third heating cycle: Elements come on: [3, 1, 2] and cycle off [3, 1, 2].

• Fourth heating cycle: pattern repeats - same as first.

Control systEM fEaturEs

advanced diagnostics

Plain English text and animated icons display detailed operational

and diagnostic information. LCD screen on the front of the water

heater displays the Sequence of Operation in real time. Fault or

Alert messages are displayed when operational problems occur.

Advanced Service menu displays a list of possible causes for current

Fault and Alert conditions to aid in servicing.

Economy Mode operation

Control system automatically lowers the Operating Set Point by a

programmed value during user defined time periods. Helps reduce

operating costs during unoccupied or peak demand periods.

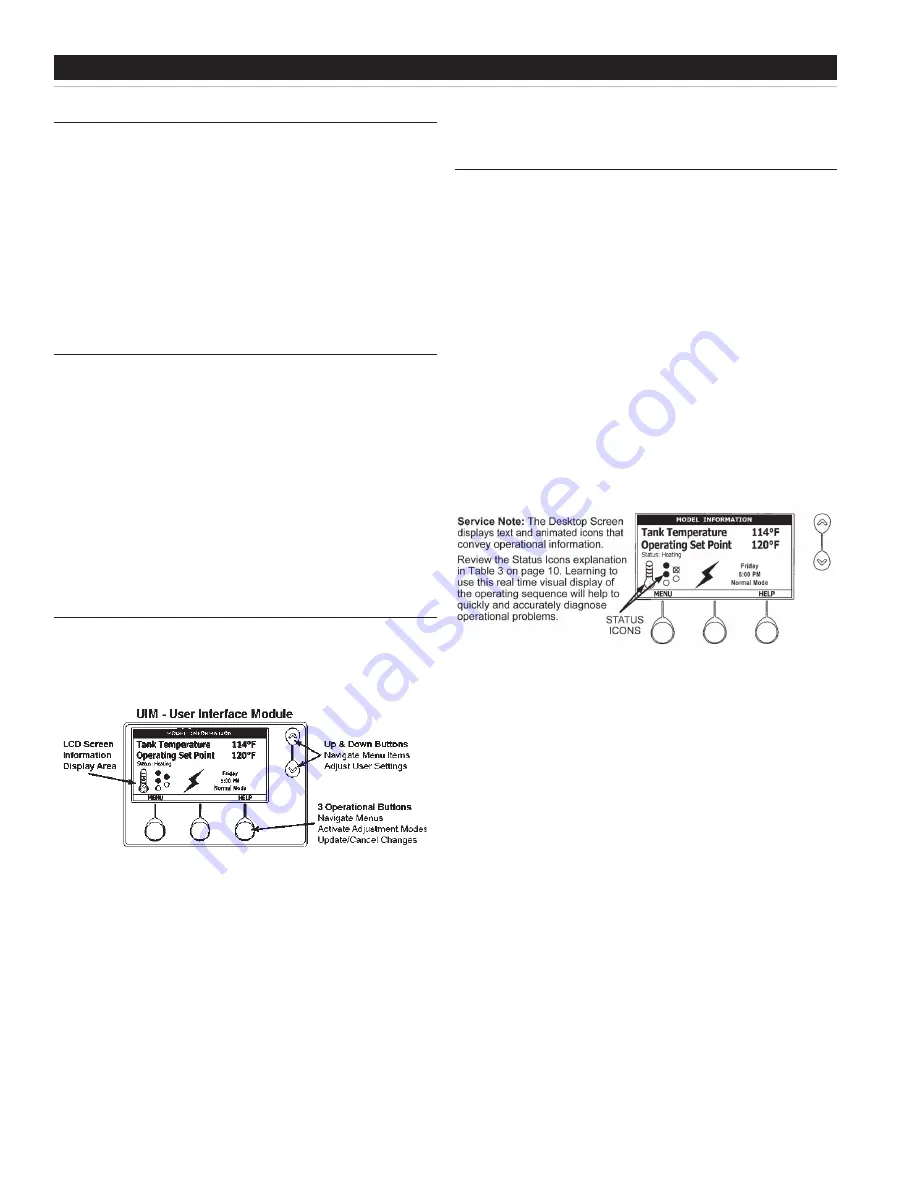

Control systEM naVIGatIon

The UIM (User Interface Module) is located on the front cabinet of the water

heater. All operational information and user settings are displayed and

accessed using the UIM. The UIM includes five snap acting (momentary)

user input buttons; an Up, Down and 3 Operational Buttons.

up & down Buttons

Used to navigate (up and down) and to select (highlight) menu items.

Also used to adjust or change (increase/decrease, on/off, set time)

various user settings.

operational Buttons

The 3 Operational Buttons are multifunctional. Their current function

is defined by the text that appears directly above each button on

the LCD screen. The function will change depending on what menu

is currently displayed or what menu item is selected. When no text

appears on the LCD screen above an Operational Button there is no

function assigned.

thE dEsktop sCrEEn

The illustration below shows the control system “Desktop Screen.”

This is the default screen. If there are no active Fault or Alert

conditions and no user input for approximately 10 minutes the control

system will return to this screen automatically.

Model Information:

Model information and menu titles are shown in

the black bar at the top of the Desktop Screen.

Tank Temperature:

Current water temperature as sensed from the

immersion Temperature Probe.

Operating Set Point:

Temperature at which the control system will

maintain tank (water) temperature in the Normal Mode. This line of

text will read Economy Set Point whenever the control system is

operating in the Economy Mode.

Status:

The Operating State of the control system is displayed

beneath the Operating Set Point.

Menu:

The left Operational Button is pressed to enter the Main Menu

where all control system menus are accessed. See Table 3 on page

10 for a list of control system menus.

Help:

The right Operational Button is pressed to access instructions

and explanations for user settings, Operating States, Status Icons,

manufacturer’s web address, technical support phone number and

service agent contact information.

Day/Time/Operating Mode:

The current time and day are also

displayed on the Desktop Screen. “Clock Not Set” will be displayed

until the time clock has been initially set. Day and Time are adjusted

in the Economy Mode Setup menu. The current Operating Mode,

either Normal Mode or Economy Mode, is displayed beneath the

day and time.

Discreet Menu Contact Information:

From the Desktop Screen

press and hold down the middle (unmarked) Operational Button for

30 seconds and then release it. This will launch a discreet menu

where personalized contact information can be entered. Installing

contractors and/or service agents can enter their company name

and telephone number. This contact information will be displayed

with all Fault and Alert messages.