7

Continued manual resetting of high limit control, preceded by higher

than usual water temperature is evidence of high limit switch operation.

The following is a possible reason for high limit switch operation:

•

A malfunction in the thermostatic controls would allow the gas

valve to remain open causing water temperature to exceed

the thermostat setting. The water temperature would continue

to rise until high limit switch operation.

Contact your dealer or service agent if continued high limit switch

operation occurs.

DIGITAL THERMOSTAT

FIGURE 3

ELECTRONIC IGNITION CONTROL

Each heater is equipped with a Honeywell ignition module. The

solid state ignition control, fig.4, ignites the pilot burner gas by

creating a spark at the pilot assembly. Pilot gas is ignited and

burns during each running cycle. The main burner and pilot gases

are cut off during the OFF cycle. Pilot gas ignition is proven by

the pilot sensor. Main burner ignition will not occur if the pilot

sensor does not first sense pilot ignition.

HONEYWELL IGNITION MODULE

S8600M Continuous Re-Try

FIGURE 4

AUTOMATIC FLUE DAMPER DEVICE

All units are equipped with an automatic flue damper that

reduces heat loss during the OFF cycles. The automatic flue

damper drive assembly is a field replaceable part and may be

obtained by contacting A. O. Smith Water Products Company

at 500 Tennessee Waltz Parkway, Ashland City, TN 37015,

1-800-433-2545. In Canada, contact A.O. Smith Enterprises

LTD., P.O. Box, 310 - 768 Erie Street, Stratford, Ontario, Canada

N5A 6T3, 1-800-265-8520.

Each automatic flue damper drive assembly is equipped with a

“Service Switch”, as shown in figure 5.

FIGURE 5

T h e “ S e r v i c e S w i t c h ” h a s 2 p o s i t i o n s : A U TO M AT I C

OPERATION and HOLD OPEN DAMPER. For normal

o p e r a t i o n t h e s w i t c h s h o u l d b e i n t h e A U TO M AT I C

OPERATION position.

If there is a problem with the damper the “Service Switch”

can be placed in the HOLD OPEN DAMPER position. When

the switch is placed in the HOLD OPEN DAMPER position

the damper disc will rotate to the open position and the

heater may be used until vent assembly is repaired or

replaced. DO NOT turn the damper disc manually; damage

will occur to the drive assembly if operated manually. Refer

to TESTING DAMPER OPERATION section of this manual

for additional information.

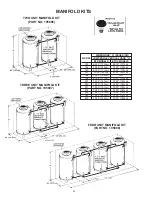

CIRCULATING PUMP

A circulating pump is used when a system requires a circulating

loop or there is a storage tank used in conjunction with the heater.

Refer to the piping diagrams in this manual for electrical hookup

information and install in accordance with the current edition of

the National Electrical Code NFPA 70. For Canada refer to the

Canadian Electrical Code CSA C22.1.

Only all bronze circulators should be used with commercial water

heaters.

Although circulators are oiled and operated by the manufacturer

some circulators must be oiled again before operating. Please

refer to manufacturer’s instructions.

DISHWASHING MACHINE REQUIREMENT

These appliances meet the NSF Standard 5 for sanitary

installations when used with the following leg kits, Part No’s.

6570-0 and 6570-7.

All dishwashing machines meeting the National Sanitation

Foundation requirements are designed to operate with water flow

pressures between 15 and 25 psi (103 kPa and 173 kPa). Flow

pressures above 25 psi (173 kPa), or below 15 psi (103 kPa), will

result in improperly sanitized dishes. Where pressures are high,

a water pressure reducing or flow regulating control valve should

be used in 180°F (82°C) line to the dishwashing machine, and

should be adjusted to deliver water between these limits.

Summary of Contents for BTR 120

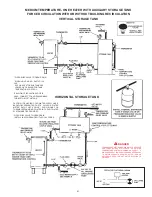

Page 25: ...25 FOR NATURAL GAS MODELS...

Page 26: ...26 FOR PROPANE GAS MODELS...