30

VENTING SYSTEM

Examine the venting system every six months for obstructions

and/or deterioration of the vent piping.

Remove all soot or other obstructions from chimney which will

retard free draft.

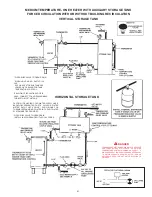

REMOTE STORAGE TANK

TEMPERATURE CONTROL

The water temperature in the storage tank (if used) is controlled

by the storage tank temperature control. The sensing element is

mounted in the hot water storage tank, see page 16.

A change in water temperature in the storage tank lower than the

tank temperature control setting will cause the sensor to activate

the circulating pump. The pump then circulates the water through

the heater where the thermostat senses the drop in water

temperature and activates main burner operation of the appliance.

If the storage tank temperature control is out of calibration, replace

with new control.

WARNING

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL

TO SHUT OFF, TURN OFF THE MANUAL GAS CONTROL VALVE

TO THE APPLIANCE.

RELIEF VALVE

At least once a year, the temperature and pressure relief valve

should be checked to ensure that it is in operating condition. Lift

the lever at the top of the valve several times until the valve seats

properly and operates freely.

If the appliance installation includes other relief valves, such as

in “remote” storage tanks etc., check their relief valve operation

with the same frequency.

WARNING

THE WATER PASSING OUT OF THE VALVE DURING THIS

CHECKING OPERATION MAY BE EXTREMELY HOT. AVOID

CONTACT AND DISCHARGE SAFELY TO PREVENT WATER

DAMAGE.

If the temperature and pressure relief valve on the heater

discharges periodically or continuously, a problem exists. This

may be due to unusually high water temperatures or pressures in

the system, or to a faulty relief valve. Contact your dealer or a

qualified service technician to find the cause of the problem and

to correct it. This may also be due to thermal expansion in a

closed water supply system. Contact the water supplier or local

plumbing inspector on how to correct this situation.

DO NOT

PLUG THE TEMPERATURE AND PRESSURE RELIEF VALVE.

WARNING

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL

TO SHUT OFF, TURN OFF THE MANUAL GAS CONTROL VALVE

TO THE APPLIANCE.

HOT WATER ODOR

On occasion, hot water may develop a strong odor. If this occurs

drain the heater completely, flush thoroughly, and refill. If the

problem persists, chlorination of the heater and replacement of

the factory installed magnesium anodes with aluminum anodes

may correct the condition.

Occasionally water softener companies recommend removal of

heater anodes for odor reasons.

CAUTION

Unauthorized removal of the anode(s) will void the warranty. For

further information contact your dealer.

ANODE ROD INSPECTION

The heater tank is equipped with anode rods to provide corrosion

control. At least once a year the anode rods should be checked

to determine if replacement is necessary. Initially the anode rods

are approximately 7/8" (22mm) in diameter with a 1/8" (3mm)

diameter steel core wire running down the center of the anode

material. THE ANODES SHOULD BE REPLACED when the 1/8"

(3mm) diameter core wire is visible as this means that the anode

material has been expended in the control of corrosion.

For models with top inlet and outlet, it is recommended that,

before removing the inner cover for cleaning, inspection or

removal of inner parts, you obtain two new nipple collars, part

no. 74060. The nipple collars on the heater will usually be

damaged when removed. New pipe collars will insure that the

seal is such as to prevent leakage of flue products when properly

installed.

NOTE:

Anode rod inspection may need to be made more

frequently in areas subject to acid rain that obtains their water

supply from surface water as the low pH will accelerate anode

activity.

CAUTION:

Close cold water inlet valve serving heater and

open nearby hot water faucet to relieve the pressure in the

heater before attempting to remove anode(s) for inspection.

RECOMMENDED PROCEDURE FOR

PERIODIC REMOVAL OF LIME DEPOSITS

FROM TANK TYPE COMMERCIAL WATER

HEATERS

The amount of calcium carbonate (lime) released from water is in

direct proportion to water temperature and usage, see chart. The

higher the water temperature or water usage, the more lime

deposits are dropped out of the water. This is the lime scale

which forms in pipes, heaters and on cooking utensils.

Lime accumulation not only reduces the life of the equipment but

also reduces efficiency of the heater and increases fuel

consumption.

The usage of water softening equipment greatly reduces the

hardness of the water. However, this equipment does not always

remove all of the hardness (lime). For this reason it is

recommended that a regular schedule for deliming be

maintained.

The time between cleaning will vary from weeks to months

depending upon water conditions and usage.

Refer to A. O. Smith booklet, Form No. 4800, entitled “Why?

When and How” for detailed description on tank inspection and

Summary of Contents for BTR 120

Page 25: ...25 FOR NATURAL GAS MODELS...

Page 26: ...26 FOR PROPANE GAS MODELS...