34

OPERATIONAL CHECKLIST

This checklist in conjunction with “TROUBLESHOOTING” and the “SEQUENCE OF OPERATION” should be used as an on-the-job

troubleshooting guide to identify the cause of incorrect system operation and suggest a remedy for its correction. Because improper

piping and wiring can result in unsatisfactory system performance, it is suggested that the installation by examined before using the

checklist. Be sure to refer to the correct piping and wiring diagram for the type of system that is installed.

REMEDY

COMPLAINT

CAUSE

USER

SERVICE MAN

*Water not hot enough.

Thermostat set too low.

Set thermostat dial to

a higher temperature.

Thermostat out of calibration. Call serviceman.

Recalibrate thermostat.

If thermostat cannot be

recalibrated, replace.

*Insufficient hot water

Thermostat set too low.

Set thermostat dial to a

*See WATER TEMPERATURE

higher temperature.

WARNING (on page 27)

Thermostat out of calibration. Call serviceman.

Recalibrate thermostat. If

thermostat cannot be recalibrated,

replace.

Main manual gas shutoff

Open main manual gas

valve partially closed.

shutoff valve to fullest extent.

Heater too small for demand. Space usage to give heater

time to restore water

temperature.

Thermostat differential is

Call serviceman.

Replace dual bulb controller if

too wide.

differential is greater than 4°F.

Heater recovery is slower.

Call serviceman.

Check gas input. If incorrect,

adjust gas pressure or replace

main burner orifice.

Draft hood not installed or

Call serviceman.

Install draft hood or baffles as

one or more flue baffles.

furnished with unit.

Water temperature too hot.

Thermostat set too high.

Set thermostat to a

lower setting.

Heater makes sounds: sizzling.

Condensation on outside of

tank - normal.

Rumbling.

Sediment accumulation on

Drain a quantity of water

bottom of tank.

through drain valve. If

Delime heater.

rumbling persists, call

a serviceman.

Ticking or metallic sounds.

Expansion and contraction-

normal.

Pounding.

Air chambers in piping have

Drain piping system and

become waterlogged.

refill. Heater must be off

while this is being done.

Combustion noises.

Too much primary air.

Adjust shutters.

Overfired heater. Incorrect

burners or orifice for types

Call serviceman.

Check and correct as necessary.

of gas used.

Water leaks.

Drain valve not closed tightly. If drain valve cannot be

closed tightly, replace.

If leakage source cannot be

Shut off gas supply to heater Repair or in case of suspected

corrected or identified, call

and close cold water inlet

tank leakage, be certain to confirm

serviceman.

valve to heater.

before replacing heater.

Gas odors.

Heater is overfired.

Shut off gas supply to

Check for sooted flue passage.

heater and call serviceman.

Check for obstructed vent line.

Check backdraft or lack of draft.

Draft hood may be improperly

installed or not sized properly.

Possible gas leaks.

Shut off gas supply to

heater and call gas

company at once.

Summary of Contents for BTR 120

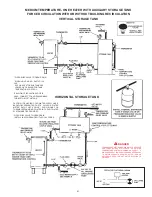

Page 25: ...25 FOR NATURAL GAS MODELS...

Page 26: ...26 FOR PROPANE GAS MODELS...