7

Vertical contact toaster

P/N 1011097 Rev. A 03/12

A.J. Antunes & Co.

caUtIOn

bread may burn. therefore toasters must not be

used near or below curtains or other combustible

walls and materials. failure to maintain safe oper-

ating distances may cause discoloration or com-

bustion.

Unpacking

1. Remove the unit and all packing materials from

shipping carton.

2. Open the Accessories Box. It should contain the

following:

• Bun Chute

• Butter Wheel Assy. (including Roller, Butter

Pan, and Heated Base

• Two Release Sheets

• Owner’s Manual

• Authorized Service Agency Directory

• Heel and Crown Label (see Step 4 under

assembling the Unit

on this page)

3. Remove all shipping tape and protective

coverings from the unit and parts.

nOte: If any parts are missing or damaged,

contact antunes technical service ImmeDIately

at 1-877-392-7854 (toll free in the U.s.) or 630-784-

1000.

equipment setup

Before placing the toaster into service, pay attention to

the following guidelines:

• Make sure power is off and the toaster is at room

temperature.

• Do NOT block or cover any openings on the unit.

• Do NOT immerse cord or plug in water.

• Keep cord away from heated surfaces.

• Do NOT allow cord to hang over edge of table or

counter.

• Connect the unit to the proper power supply.

Refer to the specification plate for the proper

voltage.

InstallatIOn

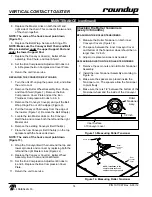

assembling the Unit

nOte: the factory has pre-installed a release

sheet over the platen (figure 1). Verify that it is

properly in place before proceeding.

1. Place the unit on a flat, sturdy location.

2. Install the Bun Chute so the hooks are installed

over the lower rear yellow Support Rod (Figure 1).

3. Hang the Butter Wheel Heated Base on the front

of the unit and install the Butter Pan and Butter

Wheel inside. (Figure 1).

3. Plug the power cord on the Butter Wheel

Assembly into the receptacle on the front of the

unit where the Butter Wheel Assembly is mount-

ed.

4. Place the Heel and Crown Label on the same side

the Butter Wheel Assembly is attached to the unit.

ImpOrtant: Do nOt plug any other power cords

into the receptacles on the toaster. these outlets

are intended for the butter wheel Only.

ImpOrtant: make sure heat shield is activat-

ing the conveyor safety Interlock switch (figure

1). the conveyors will not rotate unless the heat

shield is in place and its weight is pressing down

on the conveyor safety Interlock switch.

caUtIOn

all electrical connections must be in accordance

with local electrical codes and any other appli-

cable codes.

Hi-Limit

Control

Temperature Controls &

Temperature Display

Power

Switch

Bun Chute

Butter Wheel

Assembly

Heel Side

Crown Side

Heel/Crown

Label

Side view of

Bun Chute connected

over the bottom

rear support rod

figure 1. Vct-2010 Vertical contact toaster