21

TROUBLE SHOOTING (CONT.)

CAUSES CURES

16. Impeller partially plugged.

See item 9.

a. Increase positive suction head on pump by lowering pump or

increasing suction pipe and fittings size.

b. Sub-cool suction piping at inlet to lower entering liquid temperature.

17. Cavitation; insufficient

NPSHA (Net Positive

Suction Head Available).

c. Pressurize suction vessel.

18. Defective impeller.

Inspect impeller, bearings and shaft. Replace if damaged or vane

sections badly eroded.

19. Foot valve too small or

partially obstructed.

Area through ports of valve should be at least as large as area of

suction pipe (preferably 1.5 times). If strainer is used, net clear area

should be 3 to 4 times area of suction pipe.

20. Suction inlet not immersed

deep enough.

If inlet cannot be lowered or if eddies through which air is sucked

persist when it is lowered, chain a board to suction pipe. It will be drawn

into eddies, smothering the vortex.

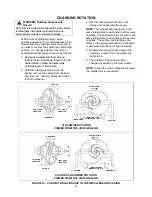

21. Wrong direction of

rotation.

Symptoms are an overloaded driver and about one third rated capacity

from pump. Compare rotation of motor with directional arrow on pump

casing. If rotation is correct with arrow, impeller may have to be turned

180°. (See CHANGING ROTATION.)

22. System head too high.

See item 4.

23. Defective mechanical seal. Repair or replace seal.

Not Enough Pressure

24. Speed too low.

See item 5.

25. Air leaks in suction piping

or stuffing box.

See item 11.

26. Mechanical defects.

See item 18.

27. Vortex at suction inlet.

See item 20.

28. Obstruction in liquid

passages.

Check to see if suction and discharge valves are fully open. Dismantle

pump and inspect passages and casing. Remove obstruction.

29. Air or gases in liquid.

May be possible to over rate pump to a point where it will provide

adequate pressure despite condition. Better provide gas separation

chamber on suction line near pump and periodically exhaust

accumulated gas. See item 17.