14

Pressure Gauges

Properly sized pressure gauges should be

installed in both the suction and discharge

nozzles in the gauge taps provided. The

gauges will enable the operator to easily

observe the operation of the pump, and also

determine if the pump is operating in

conformance with the performance curve. If

cavitation, vapor binding, or other unstable

operation should occur, widely fluctuating

discharge pressure will be noted.

Pump Insulation

On chilled water applications most pumps are

insulated. As part of this practice, the pump

bearing housings should not be insulated

since this would tend to “trap” heat inside the

housing. This could lead to increased bearing

temperatures and premature bearing failures.

STUFFING BOX LUBRICATION

Contaminants in the pumped liquid must not

enter the stuffing box. These contaminants

may cause severe abrasion or corrosion of

the shaft, or shaft sleeve, and rapid packing

deterioration; they can even plug the stuffing

box flushing and lubrication system. The

stuffing box must be supplied at all times with

a source of clean, clear liquid to flush and

lubricate the packing or seal. It is important to

establish the optimum flushing pressure that

will keep contaminants from the stuffing box

cavity. If this pressure is too low, fluid being

pumped may enter the stuffing box. If the

pressure is too high, excessive packing wear

may result; and extreme heat may develop in

the shaft causing higher bearing

temperatures. The most desirable condition,

therefore, is to use a seal water pressure 15-

20 psig above the maximum stuffing box

pressure.

PACKING

Standard pumps are normally packed before

shipment. If the pump is installed within 60

days after shipment, the packing will be in

good condition with a sufficient supply of

lubrication. If the pump is stored for a longer

period, it may be necessary to repack the

stuffing box. In all cases, however, inspect

the packing before the pump is started.

NOTE:

Packing adjustment is covered in the

MAINTENANCE section of this manual.

On some applications, it is possible to use

internal liquid lubrication (pumped liquid) to

lubricate packing. Only when all of the

following conditions prevail, can this be done:

1. Liquid is clean, free from sediment and

chemical precipitation and is compatible

with seal materials.

2. Temperature is above 32°F and below

160°F.

3. Suction pressure is below 75 psig.

4. Lubrication (pumped liquid) has lubricating

qualities.

5. Liquid is non-toxic and non-volatile.

When the liquid being pumped contains

solids or is otherwise not compatible with

packing materials, an outside supply of seal

liquid should be furnished. In general,

external-injection liquid (from an outside

source) is required when any of the above

conditions cannot be met.

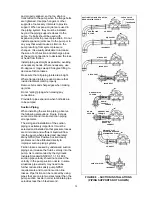

The standard stuffing box consists of rings of

packing (see assembly section for number of

rings), a seal cage, a bushing and a gland. A

shaft sleeve which extends through the box

and under the gland is provided to protect the

shaft.

A tapped hole is supplied in the stuffing box

directly over the seal cage to introduce a

clean, clear sealing medium. The stuffing box

must, at all times, be supplied with sealing

liquid at a high enough pressure to keep the

box free from foreign matter, which would

quickly destroy the packing and score the

shaft sleeve.

Only a sufficient volume of sealing liquid to

create a definite direction of flow from the

stuffing box inward to the pump casing is

required, but the pressure is important. Apply

seal water at a rate of approximately .25

GPM at a pressure approximately 15 to 20

psig above the suction pressure.

(Approximately one (1) drop per second.)

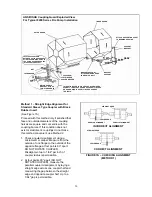

One recommended method to minimize error

in regulating flushing water is a “Controlled

Pressure System” (Figure 9). It is important to

set the pressure reducing valve adjusted to a

value slightly exceeding the maximum

stuffing box operating pressure (assuming it

is reasonably constant). A flow indicating

device will detect a failing of the bottom

packing rings allowing leakage in the pump.

External sealing liquid should be adjusted to

the point where the packing runs only slightly

warm, with a very slow drip from the stuffing