18

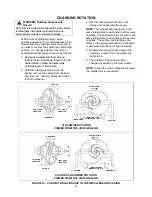

Bearings are a primary concern on pumping

units. First, dismantle the bearings; clean and

inspect them for any rusted or badly worn

surfaces. If bearings are free from rust and

wear, reassemble and relubricate them with

one of the recommended pump lubricants.

Depending on the length of time the pump

has remained in the flooded area, it is unlikely

that bearing replacement is necessary;

however, in the event that rust or worn

surfaces appear, it may be necessary to

replace the bearings.

Next, inspect the stuffing box, and clean out

any foreign matter that might clog the box.

Mechanical seals should be cleaned and

thoroughly flushed.

Couplings should be dismantled and

thoroughly cleaned.

Any pump that is properly sealed at all joints

and connected to both the suction and

discharge should exclude outside liquid.

Therefore, it should not be necessary to go

beyond the bearings, stuffing box, and

coupling when servicing the pump.

BEARING LUBRICATION – GREASE

Grease lubricated ball bearings are packed

with grease at the factory and ordinarily will

require no attention before starting, provided

the pump has been stored in a clean, dry

place prior to its first operation. The bearings

should be watched the first hour or so after

the pump has been started to see that they

are operating properly.

The importance of proper lubrication cannot

be over emphasized. It is difficult to say how

often a bearing should be greased, since that

depends on the conditions of operation. It is

well to add one ounce of grease at regular

intervals, but it is equally important to avoid

adding too much grease. For average

operating conditions, it is recommended that

1 oz. of grease be added at intervals of three

to six months, and only clean grease be

used. It is always best if unit can be stopped

while grease is added to avoid overloading.

NOTE:

Excess grease is the most common

cause of over-heating.

A lithium based NLGI-2 grade grease should

be used for lubricating bearings where the

ambient temperature is above -20°F. Grease

lubricated bearings are packed at the factory

with Shell Alvania No 2. Other recommended

greases are Texaco Multifak No. 2 and

Mobilux No. 2 grease.

Greases made from animal or vegetable oils

are not recommended due to the danger of

deterioration and forming of acid. Do not use

graphite. Use of an ISO VG 100 mineral base

oil with rust and oxidation inhabitors is

recommended.

The maximum desirable operating

temperature for ball bearings is 180°F.

Should the temperature of the bearing frame

rise above 180°F, the pump should be shut

down to determine the cause.

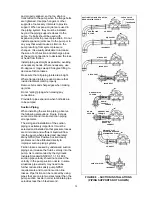

PACKING SEAL

When a pump with packing is first started it is

advisable to have the packing slightly loose

without causing an air leak. As the pump runs

in, gradually tighten the gland bolts evenly.

The gland should never be drawn to the point

where packing is compressed too tightly and

no leakage occurs. This will cause the

packing to burn, score the shaft sleeve and

prevent liquid from circulating through the

stuffing box cooling the package.

NOTE:

Eccentric run-out of the shaft or

sleeve through the packing could result in

excessive leakage that cannot be

compensated for. Correction of this defect

requires shaft and/or sleeve replacement.

Packing should be checked frequently and

replaced as service indicates. Six months

might be a reasonable expected life,

depending on the operating conditions.

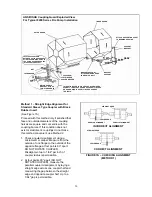

CLEANING WITHOUT DISMANTLING PUMP

A short section of pipe so designed that it can

be readily dropped out of the line can be

installed adjacent to the suction flange. With

this arrangement, any matter clogging the

impeller is accessible by removing the pipe

section.

If the pump cannot be freed of clogging after

the above methods have been tried,

dismantle the unit as previously described to

locate the trouble.