3

General Overview

The 3M Model 06531 13300 RPM, 3 HP and 3M Model 06532 6000 RPM, 5 HP Servo Rotary

Tool share many common components. The 13300 and 6000 RPM motors are capable of

continuously producing 3 and 5 horsepower respectively. The motors use a BT30 Toolholder

which allows changing out tools and media. Each of these motors provide a convenient and

effective means to spin and/or change any number of different media types to support a fully

automated workcell.

These automatic tool-changing models actuate pneumatically to secure the BT30 style

Toolholder. They are comprised of four primary components: a high-torque Servo Motor, a

pneumatic actuator, high force Belleville springs, and a component to clamp a Toolholder.

These models use a drawbar to pull the Collet/Gripper in. High force Belleville springs located

at the back of the Servo Motor tension the drawbar. Actuating the large pneumatic actuator,

located in the Clamping Housing, opens the Collet/Gripper. During pressurization the cylinder

contacts the Belleville springs and compresses them to drive the Collet/Gripper out, releasing

the Toolholder. There is no mechanism to forcibly eject the Toolholder from the Collet, so

gravity or a capturing mechanism must be used. Both models use a 30 taper to grip a

standard BT30 Toolholder. This design locks the Toolholder in the 30 tapered shaft and resists

large pull out forces. The shaft does not have locking keys, so motor indexing for tool change

is not required.

These automatic tool-changing motors are fail-safe, in that no air pressure is required to hold

the Toolholder. Therefore, the Toolholder will remain held in the Collet/Gripper even when

the air pressure is unexpectedly lost. Likewise, applying air pressure to a single input port

via a simple manual or electrically operated valve opens the Collet/Gripper and releases the

Toolholder. The design always isolates the motor bearings from the drawbar tension. This

greatly improves reliability by allowing the motor shaft to spin freely and never be subject to

any clamping forces. Both motors use sealed bearings to ensure a long life. The bearings have

additional contamination protection from a contact shaft seal. This special seal eliminates the

need for constant purge air.

During operation these motors generate considerable heat due to their high torque and

compact size. Excessive operating temperatures will significantly reduce the life of the motors.

Water Cooling is required to keep the unit within the internal temperature operating range.

The motor should never be allowed to exceed a temperature of 176˚F (80˚C). Continuously

operating the unit above 176˚F (80˚C) will cause the rotor to de-magnetize and the bearings to

fail. High temperatures will also cause the O-rings that seal the cooling water channels to fail,

possibly filling the motor with water. Flow through water cooling is provided on the motor to

allow high duty cycles without overheating.

Product Configuration / Specifications

Operating / Maintenance Instructions

Model

Power

HP

(kW)

Continuous

Stall

Torque

lb.-ft. (N·m)

Full Load

(A)

Maximum

Speed

RPM

Speed

Regulation

%

Shaft

Maximum

Axial

Load lb.

(N)

Shaft

Maximum

Radial

Load lb.

(N)

Weigh

lb. (kg)

Operating

Temperature

Optimal,

Maximum

F (C)

Thermal

Cutoff F

(C)

Max.

Coolant

Pressure:

PSI (Bar)

Insulation

Amplifier Type

06531

3

(2.2)

2.57 (3.5)

15.0

13300

5

Reversible

150 (666)

300

(1332)

28

(12.7)

122, 176

(60, 80)

212

(100)

60 (4.1)

Class F

(155°C)

Kollmorgen

®

Servo Amplifier

13300, 3M PN

06547

06532

5

(3.7)

5.6 (7.6)

19.5

6000

5

Reversible

150 (666)

300

(1332)

28

(12.7)

122, 176

(60, 80)

212

(100)

60 (4.1)

Class F

(155°C)

Kollmorgen

®

Servo Amplifier

0605, 3M PN

06545

Fastener Tightening Torque Specs

Torque

Minimum Depth

Fastener Size

in.-lbs.

ft.-lbs.

N-m

in.

mm

M4 x .7

50

4.2

5.6

0.17

4.3

M5 x .8

85

7.1

9.6

0.21

5.3

M6 x 1

140

11.7

15.8

0.25

6.3

M8 x 1.25

348

29.0

39.3

0.33

8.4

M10 x 1.5

600

50.0

67.8

0.41

10.5

Installation & Operation

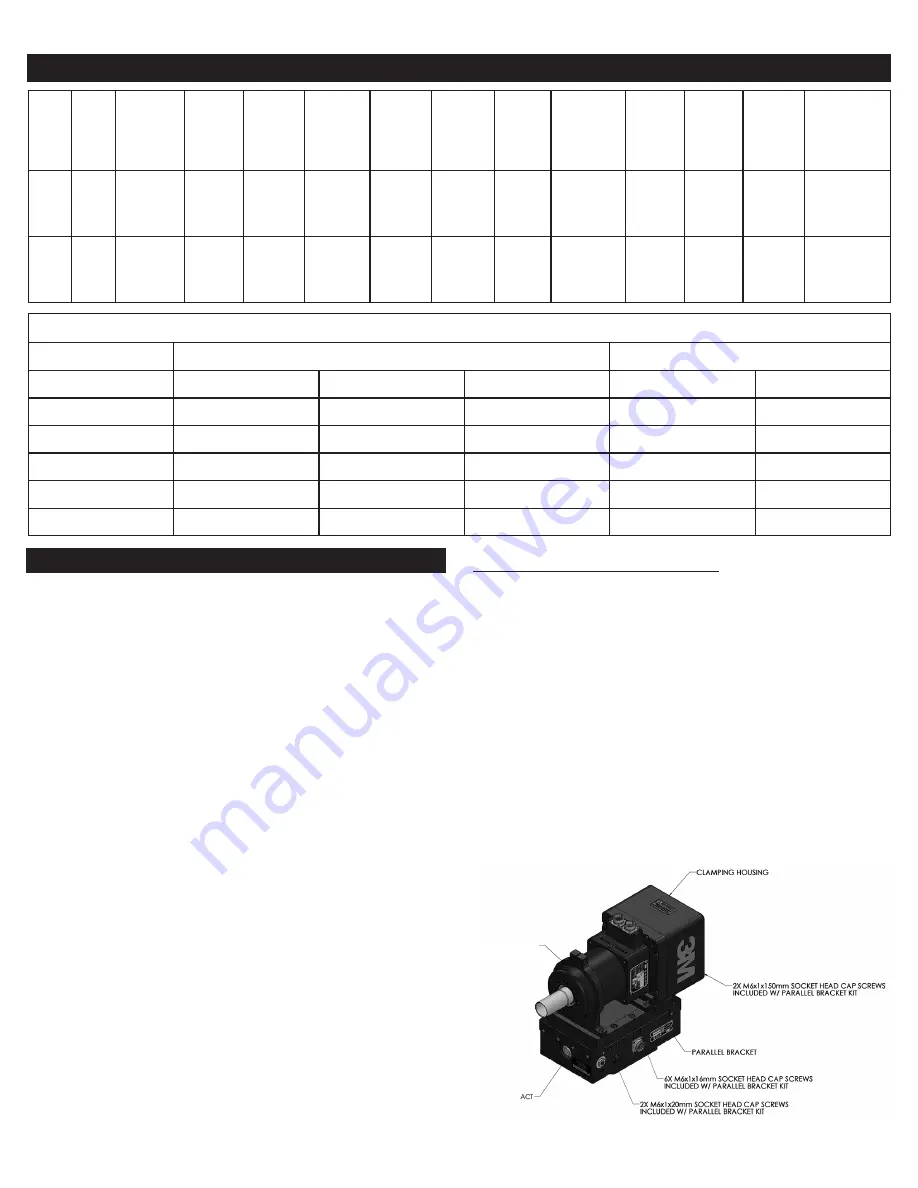

Mounting the 3M rotary tool to a 3M ACT compliant tool

The tools are designed to attach directly to the Carriage of 3M ACT (Active Compliant Tool),

using the Parallel Mounting Kit Model 06533.

The Parallel-Axis configuration is shown in Figure 1, where the tool attaches to the ACT

Carriage with the Parallel Mounting Kit. The Parallel Mounting Kit is positioned on the Carriage

and attached using the four (4) supplied M6x1x20mm Socket Head Cap Screws. The tool is

then attached to the Parallel Mounting Kit as shown, with two (2) M6x1x20mm Socket Head

Cap Screws into the front of the Motor Housing. Two (2) M6x1x145mm Socket Head Cap

Screws pass through the Clamping Housing/Mounting Plate. The fasteners must be tightened

to the torque specified in the Technical Specifications Section.

To attach the tool to an ACT in a Perpendicular-Axis configuration, position the Clamping

Housing/Mounting Plate over the Carriage as shown in Figure 2. Then secure the unit using

four (4) M6x1x145mm Socket Head Cap Screws. Tighten the fasteners to the torque specified

the Technical Specifications Section. 5mm Dowel pins can be inserted and glued into the

Carriage to align the motor. The Clamping Housings and Mounting Plate have predrilled

clearance dowel holes for this configuration.

NOTICE: Make sure that the M6x1 fasteners do not exceed a depth of 0.40” (10 mm) into

the ACT Carriage Helicoils or damage will occur.

NOTICE: Do not press Dowel Pins into the ACT Carriage, this will damage the linear rails.

3M 06531

3M 06532

Figure 1. Spindle Motor Parallel-Axis Configuration