30

3D Systems, Inc.

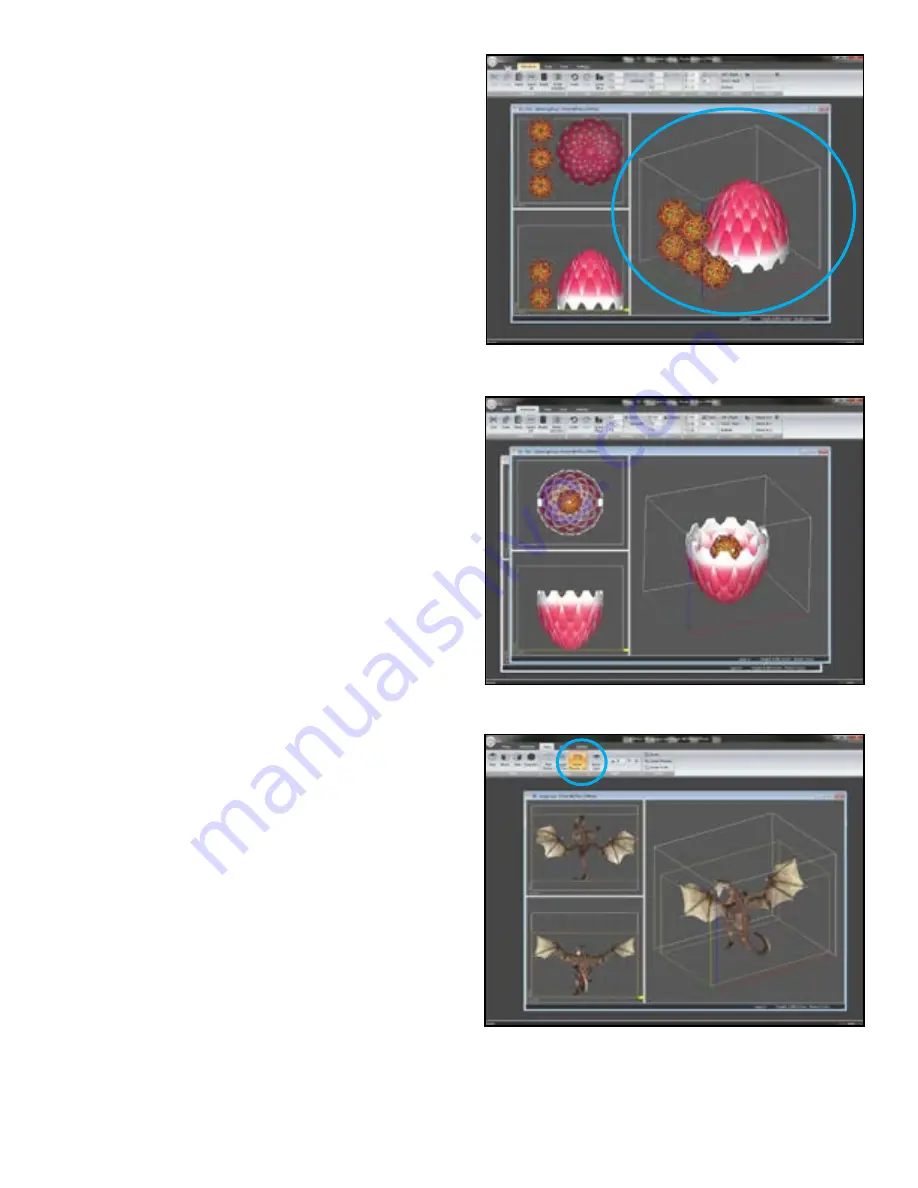

Grouping:

After parts are positioned, a greybox will frame the parts to indi

-

cate that they are

grouped

.

Moving manually/translating the part:

Parts can be manually

moved if the default position is not ideal for your needs.

•

Mouse

option – drag and place in top and side views.

You cannot move a part in the isometric view.

•

Translate

– move based on position

•

Justify

– front/back, left right, bottom

•

Rotate

– x,y,z are axes of rotation.

NOTE:

Bounding boxes can intersect as long the actual 3D model

does not touch.

Rotating a Part:

Parts being prepared for a build can be

rotated

and

scaled

to suit your needs. Primarily, a part will be opened and

prepared in a default setting.

• To rotate a part, select the part and choose

Transform

> Rotate.

In the Rotate dialog, specify the plane and

degree of rotation, and click OK.

• To keep a group of parts in the same relative orientation,

rotate the parts as a group. Select each part and then

choose

Transform > Rotate

.