32

3D Systems, Inc

.

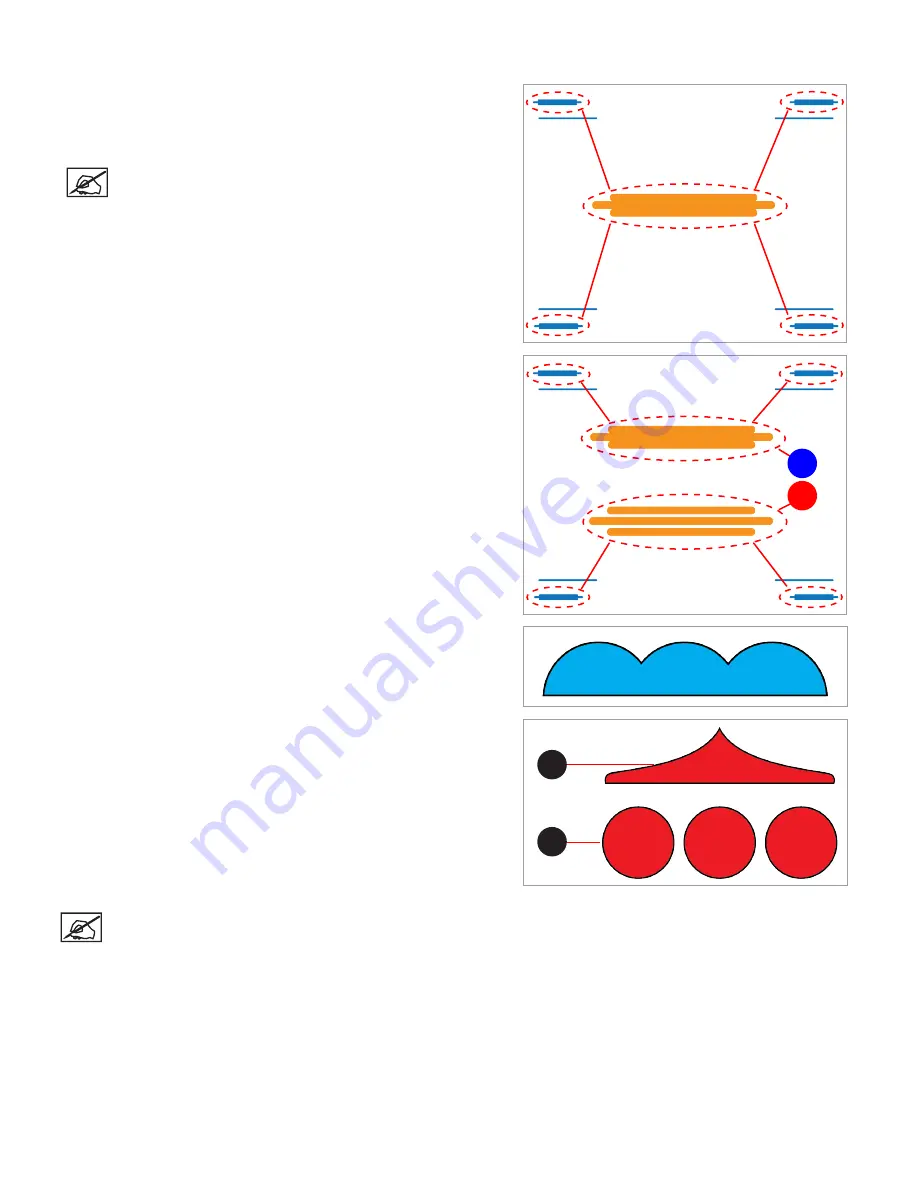

Reading the Print Pad Level Calibration Print

Correct Print Pad Level

The Print Pad Level is correct when each of the four (4) corner calibration

points have no gaps between the Print Pad Level calibration lines and the

baselines.

NOTE:

Before making any adjustments to the Print Pad Level,

the Z-Gap must be correct.

Incorrect Print Pad Level

In the illustration, there is an incorrect gap between the Print Pad Level

calibration lines and the baselines on the front of the print pad and no gap

between the Print Pad Level calibration lines and the baselines on the back

of the print pad. The front of the print pad needs to be raised.

To correct the Print Pad Level in this instance, turn the front print pad

adjuster knob counter-clockwise (left) 1-step. Reprint the file and verify that

all four corner calibration points are correct.

Acceptable Print Pattern

The Print Pad Level calibration file should print with no gap between the

Print Pad Level calibration lines and the baselines. The illustration indicates

an acceptable print pattern from a profile view.

No Gap

Unacceptable Print Patterns

If the gap between the print pad and the print jet nozzles is too small, the

Print Pad Level calibration lines will press in and scrape the baseline. If

all four corner calibration points appear like the pressed profile illustration

(A), turn the three (3) print pad adjuster knobs clockwise (right) 1-step to

increase the gap. Reprint the Print Pad Level calibration print again.

If there is a gap between the Print Pad Level calibration lines and the

baselines like the illustration (B), turn the three (3) print pad adjuster knobs

counter-clockwise (left) 1-step to decrease the gap. Reprint the Level Gap

calibration print.

NOTE:

Once all four corner Print Pad Level calibration points are correct, verify the Z-Gap to ensure that it is still correct.

Front

Back

Front

Back

√

X

Gap

Pressed

B

A