3

4.

SC10 Operation

Snore or Snooze Control. The SC10 Snore Controller monitors the electrical motor current via a 4-20mA output current

transformer (CT). By monitoring the centrifugal pump current the SC10 detects the low current when no or little fluid is being

discharged (called snoring) and stops the pump from running dry for extended periods. When low current is detected the unit

stops the pump. Note that Snore Control can work on both three-phase and single-phase motors.

The SC10 then pauses the pump operation for a time. The length of pause time before the next pump cycle is automatically

calculated. This pause time increases and decreases automatically to adjust to inflow based upon the time required for the last

pump run. The target duration of the pump run time is set via dip switches. The adaptive control algorithm will automatically

adjust the pump pause time to try to achieve the target run time.

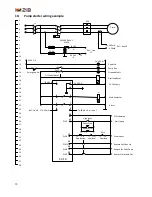

Float Switch Support. The SC10 can operate the pump with no level sensors. Or, it can utilise external level (float) switches

either as the primary means of control or in combination with the snore control. Options Include:

Timer start, Snore stop

High level start, Snore stop

High Level start, Low Level stop

Push button start, Snore stop

Push button start, Low Level stop

Push button stop, Timer start

Push button stop, High level start

The start button will start the pump anytime that it is pushed and it will continue to run until the pump is again snoring or the

low level switch activates.

The SC10 also has a pump cleaning feature. The pump will stop periodically to allow a backflush as water runs back down the

discharge hose. This helps clear the impellor and the suction strainer of debris reducing the chance of blockage and cavitation,

as well as increasing the flow rate and efficiency.

Start-up of the SC10. The SC10 will normally start the pump 30 Seconds after start-up. The pump will run until a stop condition

is reach – snoring is detected or the stop/low float is activated. This pump start will not occur if the stop/low float is active.

4.1

Snoring Detection Explained

What is Snoring?

When the pump starts sucking air (called snoring) the pump flowrate and the pump current drop. This drop in current can be

detected by the SC10. This effect is shown in the graph below.

The Stop Current Setpoint

The Stop Current Setpoint is the current below which the

SC10 considers the pump to be snoring.

As shown in this graph, the pump runs at a Normal Running

Current until it begins snoring – indicated in the graph with

Pump starts snoring here. At this point the current drops to

a lower level.

If this lower Snoring Current is less than the Stop Current

Setpoint then the SC10 stops the pump.

What is the Current Window?

The normal way of setting the Stop Current Setpoint is to

press the Set button when the pump is snoring (see section

5.6). When the Set button is pressed, the Stop Current

Setpoint is set to the measured pump current plus the

Current Window. (Stop Current Setpoint = Measured Current

+ Current Window.) This is done so that the SC10 can reliably detect the snoring condition.

An Example

The operator is commissioning the pump which has a 0-100 Amp CT. They press Start. The pump runs normal at a current of 70%

(70 Amps), then the pump snores and the measured current drops to 50% (50 Amps). The operator hears the pump snoring and

presses the Set button combination.

If the Current Window DIP switches are set for a 10% current window then the Stop Current Setpoint is loaded with 60%.