End Switch

zub machine control AG

Manual MK1/100

·

Hardware Installation

Seite 5

MK1/100

You can now carry out a test of the end switch. After activation of the end switch, an error

must occur and the red Error LED must be lit.

In order to enquire about the error, open the error enquiry window as described above. The

error message "End switch reached" must appear. Delete the error message with

ESC

and

J

(for Yes).

Switch off the power supply, before you connect the encoder to the

MK1/100

.

For error-free operation it is necessary for the encoder to be connected with the

MK1/100

via

a shielded cable. In making the connection it is important to keep the cables as short as

possible and to route them as far away from power cables as possible. Encoders with TTL or

open collector outputs can be used, which have a supply voltage of 5 V.

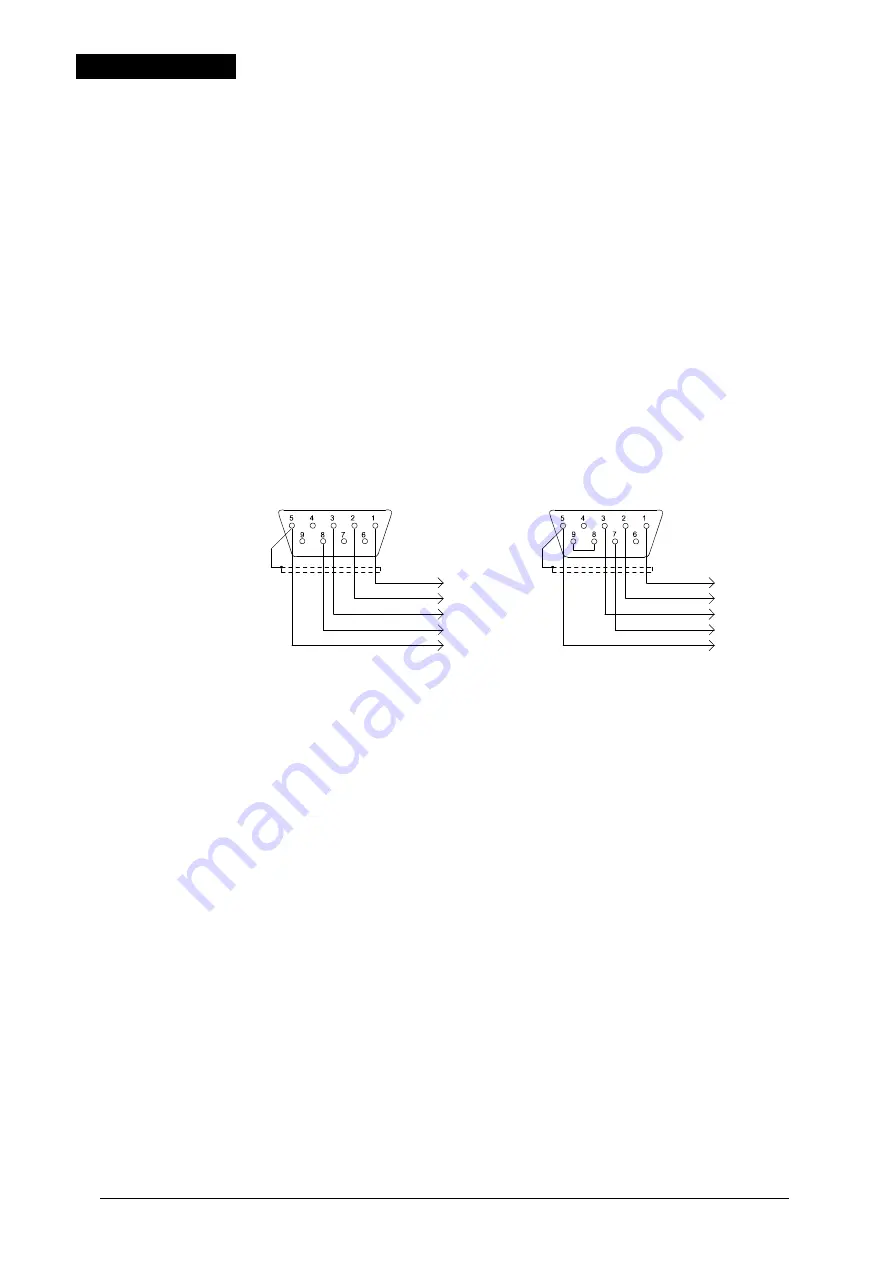

The precise allocation of the encoder jack and the significance of the signals (temporal trends

and interrelationships) can also be found in the hardware reference section.

The encoder is mounted on the motor shaft. In order to test the encoder, it is necessary that

the motor shaft is able to move freely.

The motor must not be connected during this test.

In order to test the encoder in a simple way at first, carry out an APOS test program. Select

the APOS menu item

File

→

Load.

With the keys

Pos1

and

End,

select the document "DREHGTST.M“. You can also enter the

name of the document directly. The entry must be completed with the

Enter

key.

After the APOS program has been loaded, it must be started as follows:

Leave the Editor window with the

ESC

key. Then select the menu

Execute

→

Start program

with the

cursor

keys and the

Enter

key. When the

Enter

key is pressed, the program is

processed.

In the output window, you will now see a new position value displayed every half a second.

After a full revolution of the motor shaft by hand, the position value should amount to four

times the encoder count per turn. For instance, if the encoder count per turn is 500, you

should receive a position value of

±

2000. After a further revolution in the opposite direction,

the position value should be zero.

End Switch

Incremental Encoder

! ! !

! ! !

Encoder with

negative

index impulse

Encoder

Encoder with

positive

index impulse

Encoder

+ 5 V

track A

track B

/Index

GND

screen

+ 5 V

track A

track B

/Index

GND

screen

Z&B Werkbild: mk1drehb

to the encoder

to the encoder

bridge