3

The DC controller is equipped with a charger for maintaining the battery in a

ready state and recharging the battery after use when AC power is restored.

Time for recharge depends upon the amount of power consumed by the pumping

cycle during the AC power interruption. The pump may go back to the ready run

position in a very short period of time. A completely drained battery may require

up to 24 hours for full recharge. If battery does not charge properly, the LED

battery will flash red.

PERFORMANCE

The DC pump performance at 12.7 Vdc

BATTERY SELECTION

Discharge

Feet of Head

5

(1.5 m)

10

(3 m)

15

(4.6 m)

28

(85 m)

Flow

GPM (LPM)12.7 volts

43

(163)

35

(132)

27

(102)

Shut-off

Head

SK3183

The DC emergency pump system requires a good quality, 12 volt battery

to obtain maximum pumping time during a power outage. A deep-cycle,

12 volt, 105 amp-hour marine battery or larger is recommended and will

provide approximately 5 hours of continuous pumping time in a sump pump

installation with 8' (2.4 m) of head pressure. In most installations, the pump

runs intermittently and the battery life is extended accordingly. Batteries with

top terminals are recommended for ease of installation. "Wet" cell batteries

contain acid, and proper precaution must be taken when handling. Battery

box will accommodate a maximum battery size of 13-1/2" (34.3 cm) Length x 7"

(17.8 cm) Width x 9-1/2" (49.5 cm) Height. AGM batteries also recommended.

Do not use gel batteries or automotive batteries.

© Copyright 2019 Zoeller

®

Co. All rights reserved.

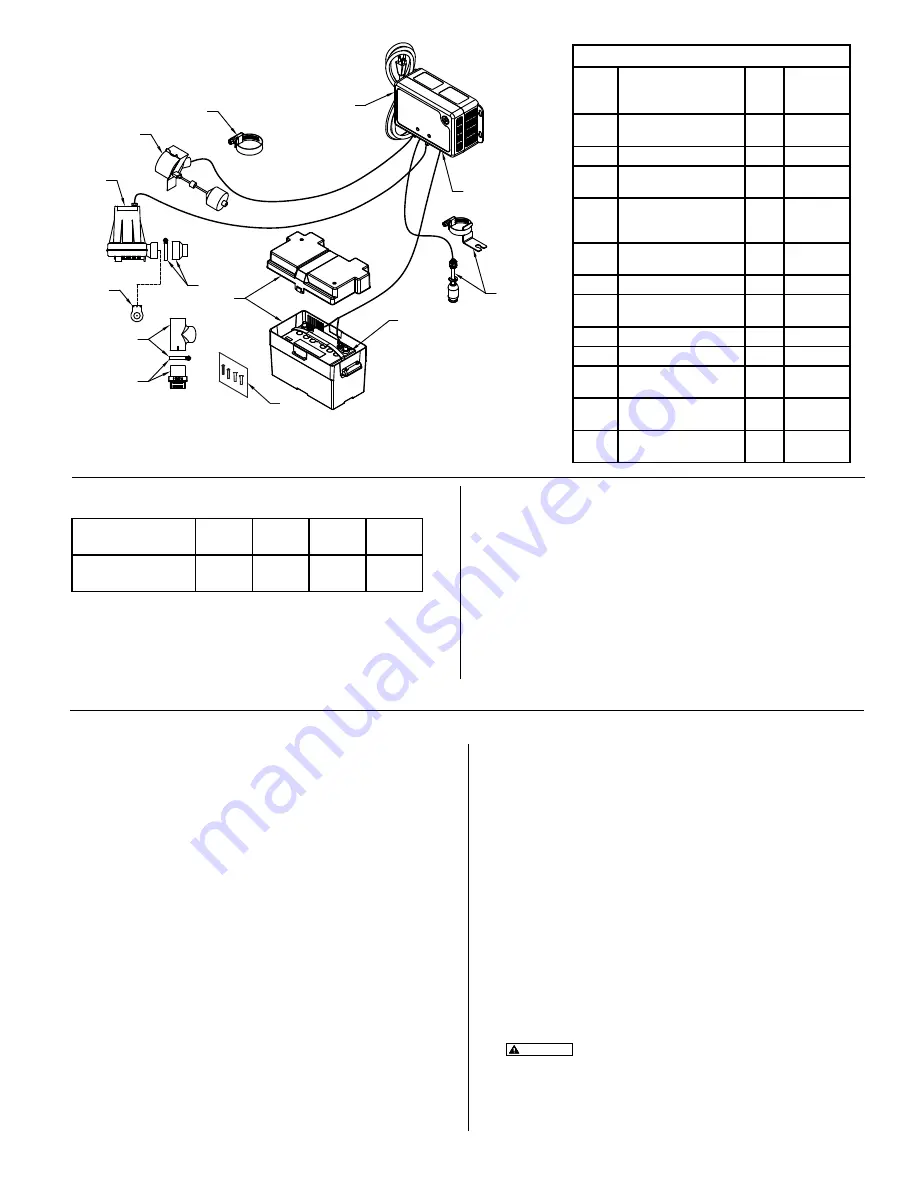

2

3

1

4

5

12

10

11

9

6

7

8

12 VOLT BATTERY

SUPPLIED BY USER

Model 508 Spin

™

Item

Description

Qty

508-C

02/19

thru Current

1

Pump 12 V DC / Backup

(service part)

1

155652

2

Flapper asm, (service part)

1

152970

3

Fitting, asm & clamp "508"

(service part)

1

152969

4

Fitting, PVC 1-1/2" (DN40)

tee/SCH 40 (pressure

fitting)

1

153766

5

Valve, check / 1.5" (DN40)

Inline / vertical

1

153772

6

Operational float

1

155654

7

Clamp, #28 Worm-SS (float

switch)

2

004287

8

Spin

™

controller

1

155978

9

Fuse, 30 amp automotive

1

016918

10

Optional high water float,

NC

1

10-4830

11

Battery box asm (box and

cover)

1

10-0764

12

Hardware pak, charger /

switch mode

2

152864

NOTE: Check float operations to ensure the hose clamp screws will not

interfere with the float operation of the primary pump.

8. Assemble the operation float assembly per Figure 3. Install float switches

as seen in Figure 1.

9. Install the operational float switch bracket above the "on" level of the

primary pump using the clamp provided. Make certain the clamp is tight

on the pipe to avoid slippage. Ensure that the "off" level of the float is 1"

(2.5 cm) minimum above the outlet of the DC backup pump. Position the

pumps in the sump and move float up and down, ensuring free movement

without interference from any obstructions inside the sump or lid. The

float switch can be moved on the discharge pipe, or the rubber stops can

be adjusted as necessary. Cut extra float rod length below lower float

stop to prevent debris from interfering with float operation.

10. Install the Spin

™

Controller (see Figure 3) by using the anchors provided.

For best cooling, install wall mount configuration. The controller should

be located at least 3' (1 m) above the sump.

11. Connect the leads from the controller to the battery terminals. Positive

(+) lead to positive terminal and black neg. (-) lead to negative battery

terminal.

CAUTION

Correct battery hook-up is essential for operation of

the system. Use wing nuts supplied with battery and eyelet connectors

on battery wire leads. The positive terminal is the larger stud, 3/8" (10

mm) diameter. The smaller stud, 5/16" (8 mm) diameter is the negative

terminal. Apply grease to the terminals to help prevent corrosion.

1. The preferred method of installation for backup pumps is shown in Figure 1.

The installation kit includes the necessary fittings and parts needed to install

as in Figure 1. A check valve is incorporated in the discharge of the backup

pump.

NOTE: Do not install in small spaces where the controller will not be

properly cooled.

2. Remove all parts from the shipping carton, and make sure all parts are

included. Refer to the parts list on page 3.

3. Select a location for the battery and the controller. The controller must be

within 8' (2.4 m) of a 115 V wall outlet and within 6' (1.8 m) of pump and basin.

Is recommented that the controller is plugged into a separate circuit from the

primary pump.

4. If the primary pump is installed, disconnect power.

NOTE: Discharge piping must be 1-1/2" SCH 40 PVC

5. Remove the discharge pipe from the pump and place it aside.

6. Solvent weld the DC Pump discharge reducer fitting to the tee as shown in

Figure 1. Ensure the O-ring is properly located on the pump discharge. Slide

the DC pump into the fitting, and tighten the hose clamp.

NOTE: The pump must be pushed all the way into the fitting to prevent the

fitting from leaking.

7. Determine the position of the DC pump and measure for discharge piping.

Use that measurement to cut the discharge pipe. Solvent weld that piece

to the tee. Measure, cut and solvent weld any remaining discharge piping

above the tee.

INSTALLATION