6

5

4

1

6

2

WHITE

RED

PUMP

MAIN

START

L1

L2

BLACK

WHITE

230 VAC 1ø

FROM CONTACTOR

RUN

START

BLACK

START

RELAY

CAPACITOR

CAPACITOR

1

2 3

GREEN

5

2

1

WHITE

RED

PUMP

MAIN

START

L1

L2

BLACK

WHITE

230 VAC 1ø

FROM CONTACTOR

START

BLACK

START

RELAY

CAPACITOR

RUN CAPACITOR

1

2 3

GREEN

2

4

1

6

5

WHITE

PUMP

START

MAIN

BLACK

L2

WHITE

BLACK

RUN CAPACITOR

RED

START CAPACITOR

L1

T2

T1

START

RELAY

3

2

1

GREEN

230 VAC 1ø

(SEE CHART)

(SEE CHART)

MODELS

START CAP.

RUN CAP.

40UF 370V

324-389UF 125V

611/621

A

© Copyright 2010 Zoeller Co. All rights reserved.

Operation

GENERAL

Zoeller pumps are lubricated and tested at the factory prior to shipment

and require minimum pre-start-up maintenance.

Maximum continuous operating temperature of pump liquid for standard

model pumps must not exceed 140° F (40° C). For longest service life all

pumps should be totally submerged on long pumping cycles and a maximum

of ½ hour run time per hour.

These units are not designed to handle liquids other than water or

sewage. If pump is used in water contaminated with heavy, viscous, or

abrasive materials, the warranty will be voided.

NAMEPLATE DATA

The nameplate, located on the top of pump, indicates specifi c information

about the construction of the pump. The model number, date code, and

serial number information should be recorded on the front page in the

“Owner’s Information” section of this manual.

SHORT TERM STORAGE

If pump is to be stored, the following is advised:

• Store pump inside whenever possible or cover with some type of protective

covering.

• Tape or seal in plastic bag the terminal ends of wire leads.

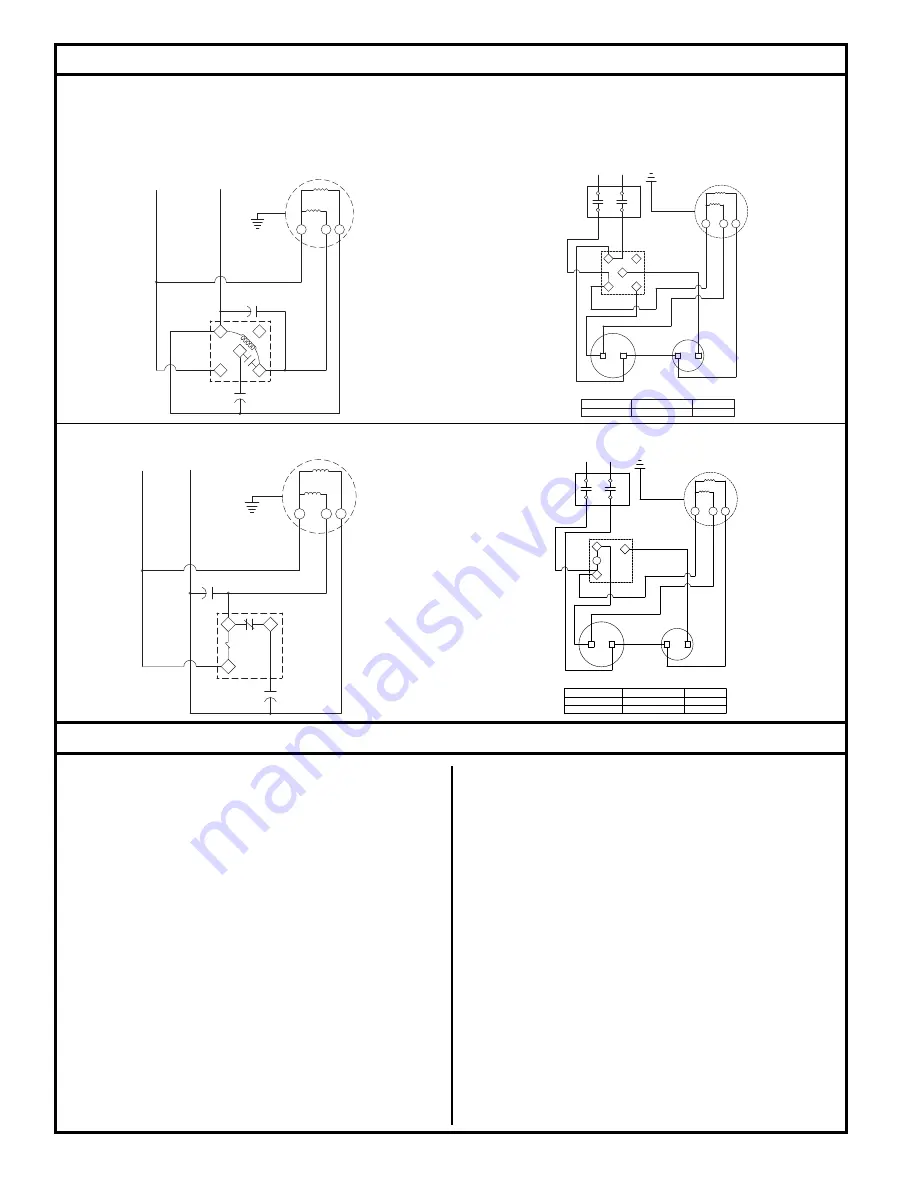

Single Phase Installation

All single phase models require start capacitor, run capacitor and relay in the circuit to start and operate properly. These components can be pur-

chased separately or prewired in Zoeller control panel. For components purchased separately used the diagram for installation and hookup.

Single phase models are nonautomatic. To operate automatically a control panel must be added to the power circuit. Follow the instructions

provided with the panel.

WIRING DIAGRAM

COMPONENT LAYOUT

ZEPA0539

ZEPA0477B

WIRING DIAGRAM

ZEPA0537

COMPONENT LAYOUT

ZEPA0540

MODELS 611 / 621

USING SUPCO PR90

RELAY BEFORE 10/1/07

MODELS 631 / 641 / 651

AND 611 / 621 USING GE

RELAY AFTER 10/1/07

• Spray coat unpainted surfaces with rust inhibiting oil.

• The impeller should be rotated every six months in order to keep the

seals lubricated and not develop a permanent set.

If panel is to be stored, the following is advised:

• Store the panel inside whenever possible and leave in the shipping

box.

• All openings shall be sealed.

• Store in an upright position.

• Do not stack anything on top of panel.

START-UP PROCEDURE

Before placing the equipment into operation the following checked:

• Correct pump rotation (3 Phase units only).

• Clean pit.

• Panel dry and securely installed.

• Floats positioned properly.

• Discharge valves open.

• 3/16” vent hole drilled in pipe between check valve and pump.

(Continued on next page)

2

1

5

WHITE

PUMP

START

MAIN

BLACK

L2

WHITE

BLACK

RUN CAPACITOR

RED

START CAPACITOR

L1

T2

T1

3

2

1

GREEN

230 VAC 1ø

(SEE CHART)

(SEE CHART)

R

RELAY

START

START CAP.

MODELS

RUN CAP.

631/641/651

270-324UF 250V

50UF 370V

611/621

216-259UF 125V

40UF 370V