MAINTENANCE

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

32

ZI-RPE160C

17.3

Changing the engine oil

N O T I C E

Waste oils are toxic and must not be released into the environment!

Contact your local authorities for information on proper disposal.

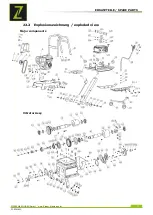

1. remove the hose (1) from the holder (2) to drain the

oil.

2. Remove the screw on the hose (3) for draining.

Collect the drained oil in a container and dispose of it

properly!

3. tighten the oil drain plug again after draining.

4. Fill up with new oil through the opening (4) (see

section Check engine oil level). Use only high-quality

engine oil, e.g. SAE30 or 15W40 or comparable

17.4

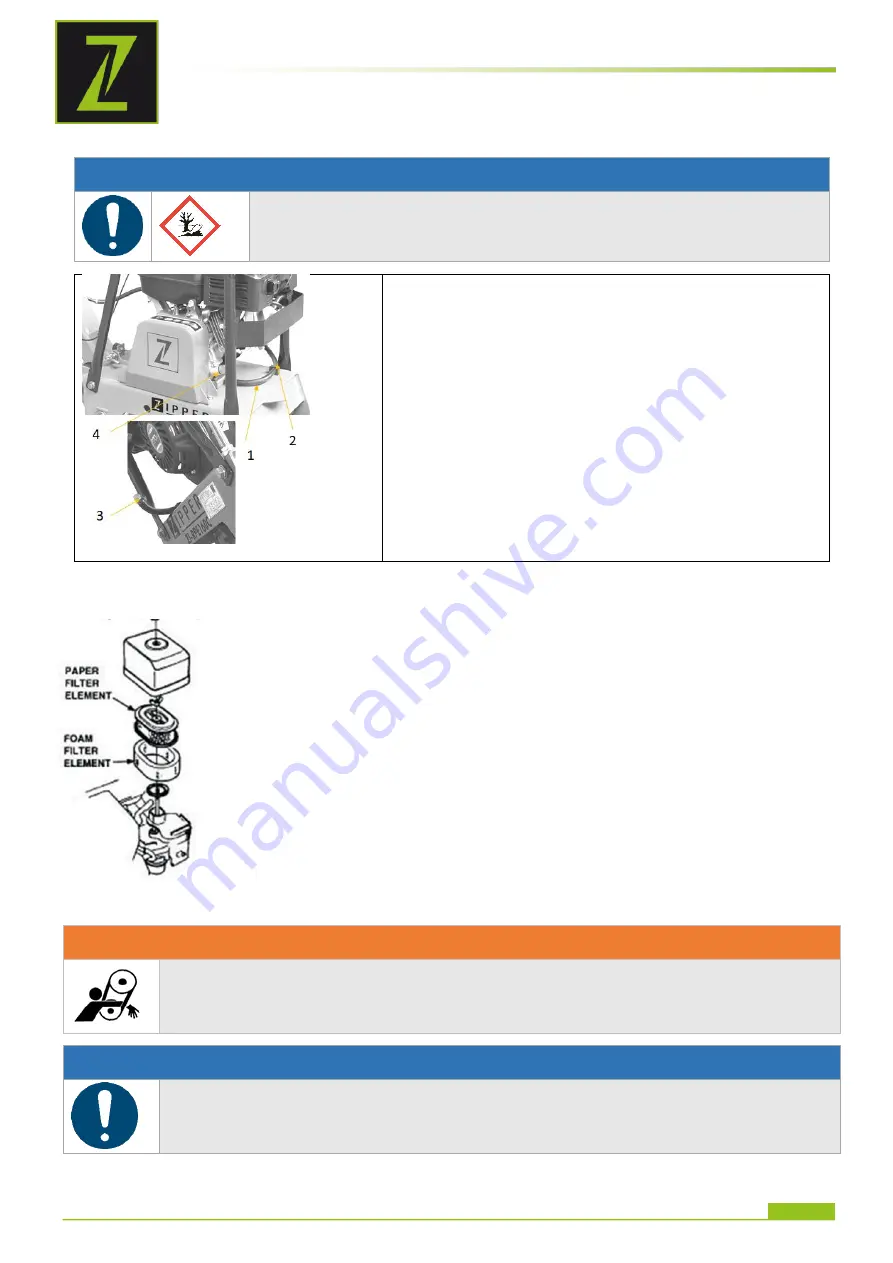

Changing the air filter

A contaminated air filter can contribute to problems starting the machine, loss

of performance during operation and shorten engine life.

Zipper Machines does not accept any liability for engine damage caused by

failure to clean the air filter regularly.

To clean the air filter, first loosen the wing nut on the air filter housing,

remove the cover (foam filter element) and remove the air filter cassette

(paper filter element). Clean both elements mechanically with a soft brush.

If only the air filter cassette is to be cleaned, blow a dry jet of compressed air

from the inside against the filter until all dust has been removed.

An air filter change is necessary when:

The engine power drops and the fuel consumption increases at the

same time.

the oil consumption increases

the starting of the engine becomes more difficult

17.5

Checking and replacing V-belt and coupling

W A R N I N G

Warning of danger of detection/trapping in! Never attempt to check the V-belt

while the engine is running. Your hands could get caught between the V-belt and the

clutch. Serious hand injuries are the result.

N O T I C E

If the vibratory power of the machine - regardless of the number of operating hours

- suddenly decreases or stops completely during normal operation, first of all check

the V-belt and clutch.