25

Installation instructions

805845UK v1.02 July 2018 - G4 Command Centre

Technical support

Tel: 0345 6 005 005 Email: [email protected] www.zipwater.co.uk

STORAGE WARNING

The cylinder contains 1.2kg of CO

2

and should be installed in a well ventilated area.

You can have serious health problems if breathing air containing concentrations of CO

2

up to 15000ppm

(1.5%) for more than 10 minutes. Proper ventilation must be provided to ensure that, in case of escape,

concentrations of CO

2

remain below this level.

See gas cylinder and MSDS sheet for complete list of warnings.

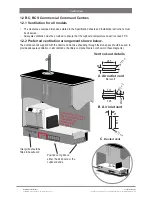

4.1

Secure the cylinder

Secure the gas cylinder supplied to a suitable wall, within 1 metre of the Command Centre, in an upright

position. This is undertaken by screwing the metal bar holding the hook-and-loop strap to a cupboard wall,

200mm above the floor or base of the cupboard. Make sure the gas cylinder can stand in place before

securing to the wall. Due to regulatory requirements the gas cylinder must be stored securely and in an

upright position.

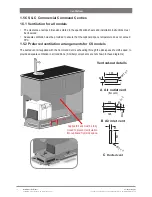

4.2 Connect the regulator

Remove the gas cylinder from the strap. Make sure the regulator

knob is turned fully clockwise to the end-stop before fitting.

Screw the regulator (clockwise) onto the cylinder. Be aware that

some CO

2

may be discharged from the connection between the

cylinder and the regulator when assembled together. Any CO

2

released will be cold. Screw on the regulator to stop this leakage.

Note

The leaking CO

2

will be cold.

4.3 Connect the gas hose

Connect the threaded end of the braided gas hose to the regulator. Then connect the push fit fitting to the top

of the Command Centre via connection marked ‘CO

2

IN’.

To turn the gas on, rotate the regulator knob anti - clockwise to

the end stop.

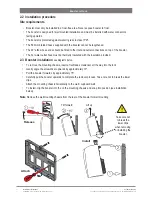

4.4 Test for gas leaks

Using soapy water perform a leak test. Apply the soapy water

to the gas connections using a sponge or brush. If any bubbles

appear and grow, there is a gas leak at the connection. Clean

away the soapy residue and tighten or refit the leaking connection. Make sure the gas is turned off when

tightening or refitting the leaking connection.

Refit the gas cylinder to the hook-and-loop strap. Ensure the cylinder is in an upright position.

!

Turn the knob fully

clockwise before fitting

the regulator

Closed

Open

Section 4

CO

2

Cylinder installation