OWN

ER’S MANUAL - 7 - I-PLAS25/40

INSTALLATION INSTRUCTION

The machine is equipped with power voltage compensation device. When the power voltage fluctuates between±15% of

rated voltage, it still can work normally.

When the machine is used with long cables, in order to prevent voltage form going down, bigger section cable is

suggested. If the cable is too long, it may have great affluence on the arc-striking or other performance of cutting system,

e.g. the HF arc-striking performance get weak or the system work abnormally. So cables of configured length are

suggested.

1. Make sure intake of the machine is not blocked or covered to avoid malfunction of cooling system.

2. Ground the cables with section area no less than 6mm

2

to the housing, the way is connecting screw in the back of

the power source to ground device, or make sure ground terminal of power socket is firmly connected. Both ways

can be used for absolute safety.

3. Use pressure-resisting air pipe to connect the air intake and compressed air source, tight the joint with hoop or other

ways in case of gas leaking. Dry gas with suitable pressure and flow should be supplied. If your air source cannot

meet above requirements, you should consider using sole compressor with enough power and air-decompressing

filter to ensure the machine work normally.

4. Install the air-electricity system plug

to relevant socket on the panel and

fix it clockwise. Air plug of the cutting

torch and arc-keeping cable should

be connected to relevant socket, and

tighten the joint screw.

5. Put cable plug to the socket on the

panel and fix it clockwise. On the

other hand, clamp the work piece

with earth clamp.

6. According to input voltage grade,

connect power cable with power

supply box of relevant voltage grade.

Make sure there is no mistake and

the voltage of power supply does not

exceed permission range.

7. Connect the cabled following the

right schematic, next steps can be

performed then.

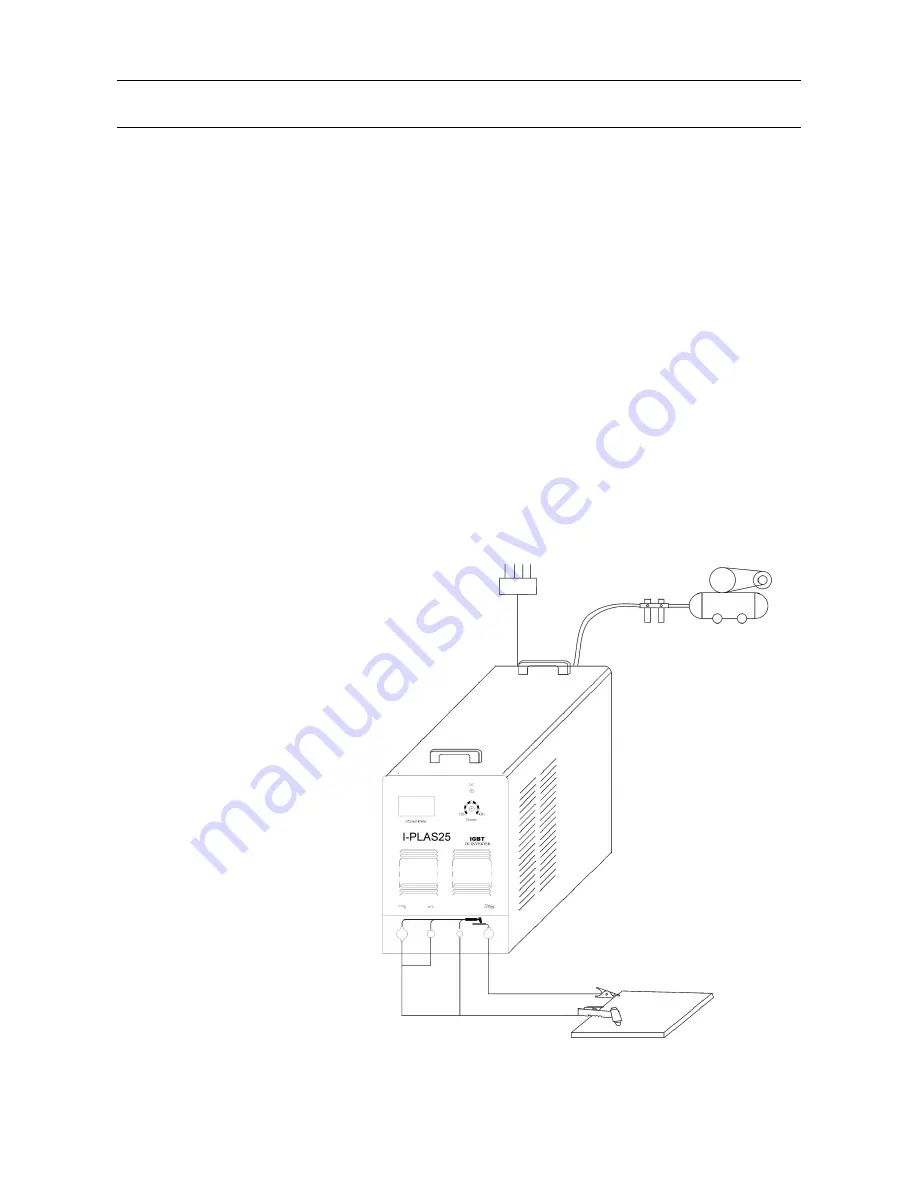

Machine Installation Instruction:

Power supply

(3phase ~380V)

Out

In

Air

compressor

Air regulator

Workpiece

Earth clamp

Cutting torch

Содержание I-PLAS 25

Страница 1: ...ZIKA OWNER S MANUAL I PLAS 25 40...