8 Service and maintenance

8.1

General notes on maintenance

"

Observe the safety-at-work regulations!

"

Disassembly of the elevator machine is not permissible.

"

Never use a high-pressure cleaner (for example steam jet cleaner) for cleaning the elevator

machine!

"

Take note of abnormal operating noise.

"

The bearings have a lifetime lubrication. There is no possibility to relubricate. Maintenance is not

necessary for the bearings.

To check the brake wear the following instructions have to be referred:

It is not possible to adjust the brakes. The brakes cannot be readjusted. Replace the both brake rotors

when the maximum air gap has been reached.

The wear to the brake is checked with the brake closed, therefore:

"

Make sure that all moving parts have stopped, secure them mechanically if required!

"

Make sure that the elevator can not be moved from any other person than the one who does the

check!

8.2

Inspection intervals

During commissioning or

after the

fi

rst 3 months

every year

Distance of the rope guardx

x

Check vibration isolation

The thickness of the vibration isolation must be the

same on the right and left.

x

x

Checking the air gap of the brake

x

x

Visual inspection of the mounting screws on the hous-

ing, brakes and traction sheave.

The locking compound must be free of damage.

x

x

Check the traction sheave if worn out

x

Check the microswitch/inductive proximityswitch

x

Table 8-2

Note: All

fi

xing screws on the housing, brakes and traction sheave are marked with locking varnish.

That means a loosened screw is optically visible. If a screw does get turned, it must be tightened

using the prescribed tightening torque, the old locking varnish needs to be removed and marking has

to be made again.

8.2.1

Checking the air gap

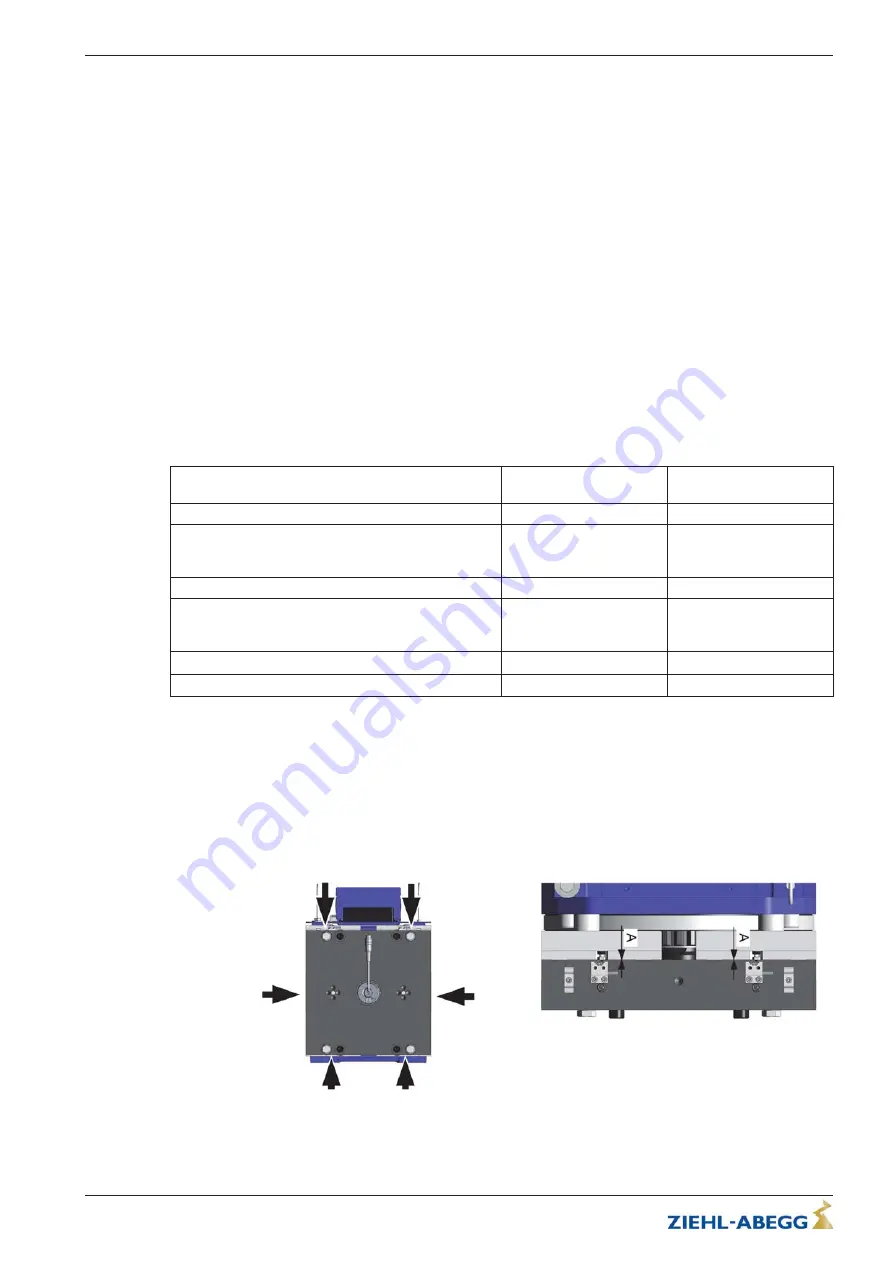

Figure 8-2-1-01 - Air gap measurement position

Figure 8-2-1-02 - Air gap measurement

Translation of the original operating instructions

ZAtop

–

model series SM200.40E/SM200.45E

Service and maintenance

A-TBA21_01-GB 2021/30 Index 003 Part.-No. 01013507-GB (EU-BD 1112)

27/64