Figure 8-19

Figure 8-20

Brake wiring diagram with micro switch

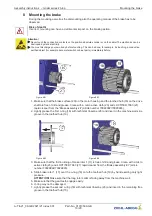

Figure 8-21

1 Brake release monitoring

2 Brake

3 Shown with currentless brake

Brake wiring diagram with inductive proximity

switch

Figure 8-22

1 Brake release monitoring

2 Brake

3 Minimum strength 2 mA DC

4 Operating voltage range 10 - 30 V DC

5 Shown with currentless brake

40. Connect the magnet coils, the release monitoring and varistors (4) according to the wiring

diagram (28), see Figure 8-21 and Figure 8-22, inside the top cover of the junction box (1).

41. Fit strain reliefs (3).

42. Close the cover (1) of the junction box.

43. Perform brake test (see chapter "Brake operating instructions - brake test" in the appendix at the

original operating instructions).

44. Carry out the alignment of the absolute encoder (9) corresponding to the original operation

instructions of the frequency inverter.

9 Functional test on microswitch/inductive proximity switch for re-

lease monitor

After mounting of the brake, a functional test must be performed on the micro switches/inductive

proximity switches (see chapter "Brake operating instructions - release monitor" at the original operat-

ing instructions).

If the function is not available, please check the causes that may prevent the actuation of the micro

switches/inductive proximity switches (see chapter "Brake operating instructions - release monitor" in

the appendix). The micro switches/inductive proximity switches will otherwise have to be readjusted

(see the chapter "Assembly and adjustment of release monitor with micro switches or inductive

proximity switches" in the appendix at the original operating instructions).

Assembly instructions

–

model series ZAtop Functional test on microswitch/inductive proximity switch for release

monitor

A-TIA21_08-GB 2021/21 Index 001

Part.-No. 01013509-GB

15/20