Maintenance and Installation Instructions

Edition 11.07.2006

17 of 30

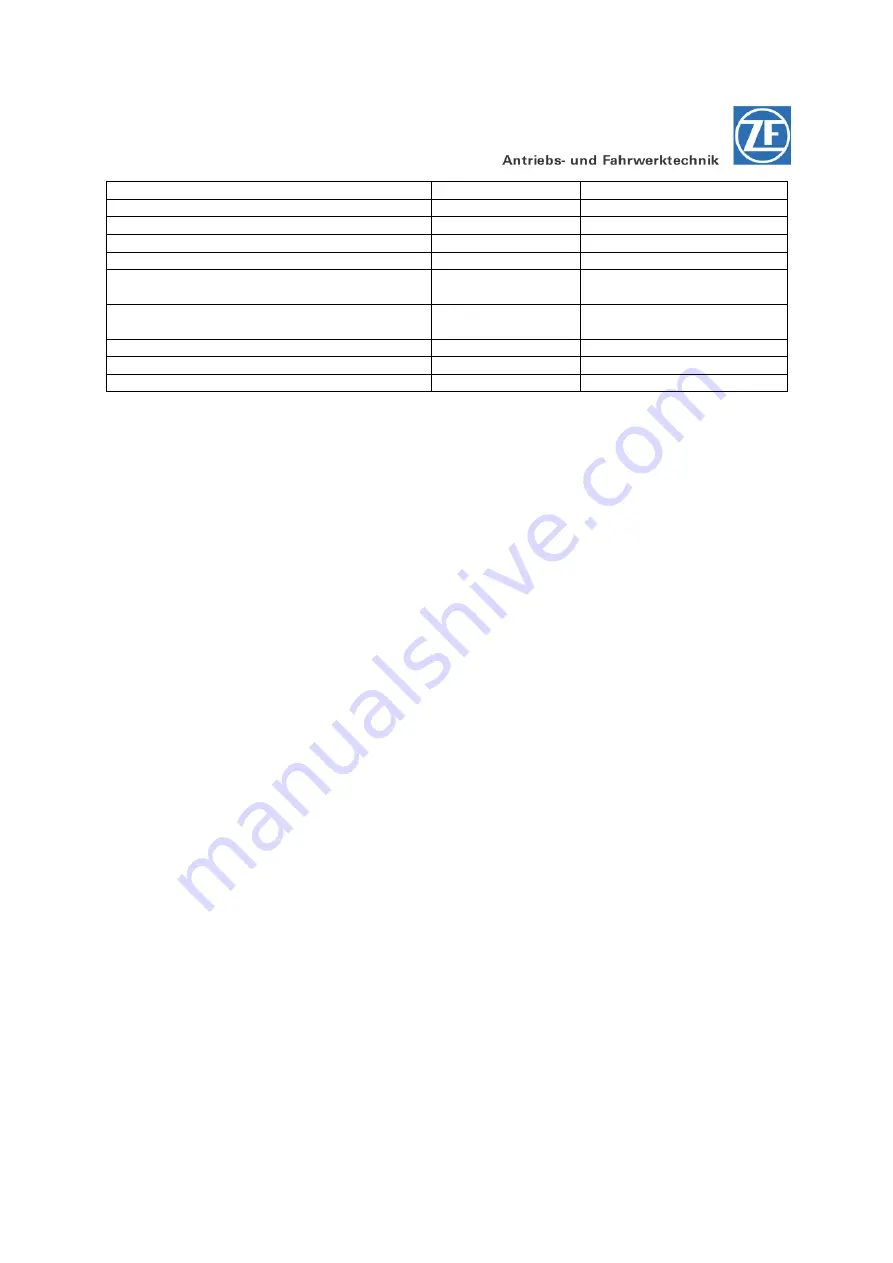

Lubricants

Description

Temperature range

Manufacturer

Aralup LFZ 1

-25°C to +250°C

ARAL

Energol WRL

0°C to +80 °C

BP

CARDREXA DC 1

-20°C to +120°C

ELF

SURRET FLUID 4k

-20°C to +100°C

ESSO

CRAFLOSCON CG 901 Manual lubrication

CRAFLOSCON C-SG-0 Plus Spray lubrication

-20°C to +150°C

Klüber

Mobiltac A Manual lubrication

Mobiltac D Spray lubrication

1)

-30°C to +120°C

Mobil

Cardium Fluid C

-30°C to 60 °C

SHELL

Crater 2 X Fluid

-20°C to +120°C

TEXACO

Grippa 33 S

-20°C to +80°C

Castrol

Table 02 „Lubricants for teeth“

The sequence of the indicated lubricants is no reference to their quality. Lubricant-specific questions have

to be clarified with the respective lubricant manufacturer.

Pivoted Connection – Roller Chain Steering

Components of the pivoted connection

(see Fig.13, Page 18

)

Fixing of the roller chain (Item 01) on the chain flange (Item 02) is made by a chain tensioner (Item 03)

with an adjustable element (Item 04).

Sixteen (16) holes (Item 05) on the plane face of the chain guideway allow fixing of the chain tensioner at

the most suitable mounting position, which is opposite to the chain pinion.

Chain tensioner

The chain tensioner is designed for mounting of the following DIN – Simplex-Roller Chains:

•

Single roller chain 5/8“ x 3/8“ DIN 8187 (European Design),

•

Single roller chain 3/4“ x 7/16“ DIN 8187 (European Design)

Tensioning of the roller chain is made via the tensioning bolt and the adjustable element of the chain

tensioner.

With the chain tensioner an overall length of the chain of approx. 25 mm can be adjusted.

Approx. 12 mm of it can be compensated via the adjustable element and the tensioning bolt, the rest by

means of the two holes in the chain tensioner.

We recommend that the roller chain in new condition is attached on the first bore of the chain tensioner

and to use connecting elements (chain joints, Item 06 and Item 07) in accordance with DIN 8187 / 8181.

(Fig. 07)