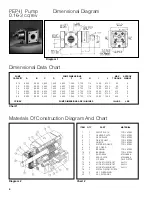

PEP-II Pump

0.16-3 cc/rev

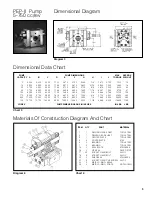

ITEM

QTY

PART

MATERIAL

1

1

FRONT PLATE

TOOL STEEL

2

1

CENTER PLATE

TOOL STEEL

3

1

REAR PLATE

TOOL STEEL

4

1

DRIVE SHAFT

TOOL STEEL

5

1

ARBOR

TOOL STEEL

6

2

METERING GEAR

TOOL STEEL

8

2

KEY, GEAR

9

2

BEARING

TOOL STEEL

10

2

BEARING

TOOL STEEL

11

1

RHEOSEAL

STAINLESS

13

1

SEAL PLATE

STAINLESS

14

1

LIP SEAL

FILLED PTFE

15

6

SOCKET HEAD BOLT

ALLOY

16

4

SOCKET HEAD BOLT

ALLOY

17

4

SOCKET HEAD BOLT

ALLOY

18

2

METAL C-RING, PORTS

19

2

KEY, D-BEARING

20

1

KEY, EXTERNAL

PUMP

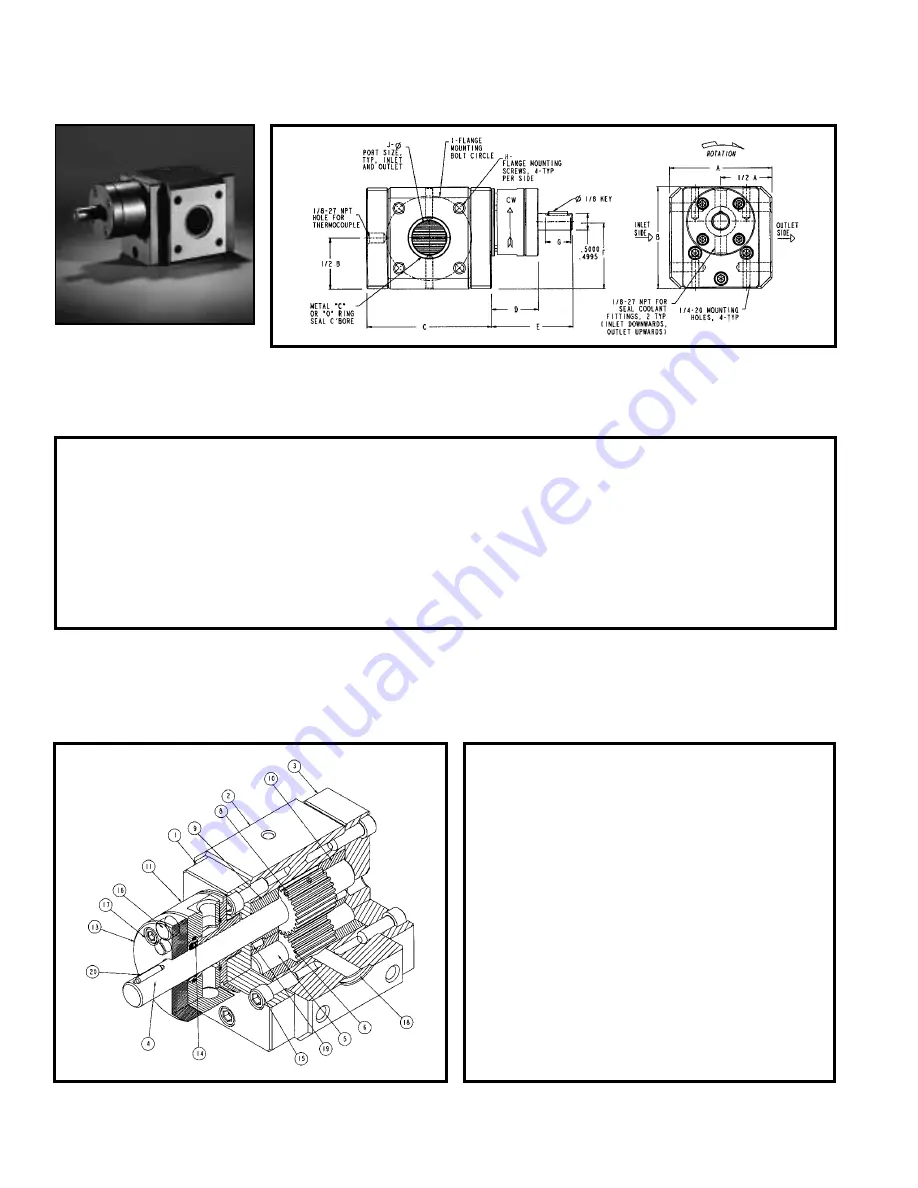

PUMP DIMENSIONS MAX

APPROX

CAPACITY

A

B

C

D

E

F

G

H

I

J

TORQUE

WEIGHT

0.16

3.000

3.000

2.860

1.400

2.400

1.960

0.750

1/4

1.500

0.125

80

9

0.3

3.000

3.000

2.860

1.400

2.400

1.960

0.750

1/4

1.500

0.125

80

9

0.6

3.000

3.000

2.860

1.400

2.400

1.960

0.750

1/4

1.500

0.250

195

9

1.2

3.000

3.000

3.650

1.400

2.400

1.960

0.750

5/16

2.500

0.750

410

9

1.8

3.000

3.000

3.650

1.400

2.400

1.960

0.750

5/16

2.500

0.750

410

9

3.0

3.000

3.000

3.650

1.400

2.400

1.960

0.750

5/16

2.500

1.000

600

9

CC/REV

PUMP DIMENSIONS ARE IN INCHES

IN-LBS

LBS

Materials Of Construction Diagram And Chart

Diagram 2

Chart 2

Chart 1

Dimensional Data Chart

Diagram 1

Dimensional Diagram

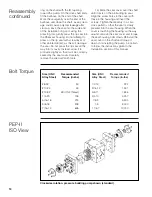

4