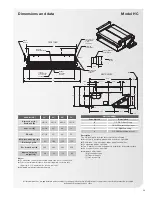

Handling and installation

Installer to provide the

following:

n

n

A mounting system or frame.

This frame should elevate the

unit above the floor such that

the unit's air discharge meets

the bottom of the supply air

grille without any significant

gaps, as well as allow for

piping or the condensate drip

tray to drain condensate from

the unit (when required).

n

n

All secondary water piping

and valves including isolation

valves on the supply and

return, balancing valves, flow

control zone valve and other

valves/controls as specified.

n

n

All mounting hardware

(threaded rods, nuts, etc.) and

primary air flexible ducting.

n

n

Condensate drainage from the

drip tray outlet, where required.

Installation

n

n

Check the unit labeling to

ensure that the proper unit

is being installed at each

location.

n

n

Determine the orientation of

the air and water connections

in relation to the site plan.

n

n

Check to ensure there is

adequate space within the

room enclosure for the

installation of the unit and

to make the piping and duct

connections.

n

n

Check the installation space

for the unit to ensure adequate

clearance to remove the lint

screen during maintenance.

n

n

Ensure the return air path to

the unit is clear and does not

restrict airflow to the unit.

n

n

Position the unit in the enclosure

and fix it to the supporting frame

by the mounting brackets. Ensure

that the unit's air discharge meets

the bottom of the supply air grille

without any significant gaps.

While all equipment is designed for

durability and fabricated with heavy

gauge materials and may present a

robust appearance, great care must

be taken to assure that no undue

force is applied to the coil, piping,

drain connection or other delicate

components during handling.

Wherever possible, all units should

be maintained in an upright position

and handled by the chassis, plenum

sections or as close as possible to

the mounting points.

Although Zehnder Rittling does not

become involved with the design

and selection of support methods

and/or components, it should be

recognized that unacceptable

operating characteristics and/

or performance may result from

poorly implemented unit support.

Additionally, proper clearance must

be provided for service and removal

of the equipment.

Anchoring the equipment in place

is accomplished by hanging vertical

units from the mounting strip, using

the mounting points provided on

horizontal units and positioning

the unit on a level plane. The drain

pan is pitched within the unit to

provide proper drainage when the

unit is installed level. Care must be

taken to ensure that the drain pan

does not slope away from the drain

connection.

The type of mounting device is

a matter of choice, however the

mounting point should always be

that provided in the chassis.

Improper mounting could

result in the unit falling from its

position, causing personal injury

or even death.

After mounting the unit, it is then

ready for the various service

connections such as water and

drain (where applicable). At this

time it should be verified that

the proper types of services

are actually provided to the

unit. On those units requiring

chilled water and/or hot water,

the proper line size and water

temperature should be available

to the unit.

24

Содержание HC

Страница 1: ...i Cooling Fresh Air Clean Air Heating Induction Unit Installation Operation and Maintenance...

Страница 34: ......

Страница 35: ......