12

5

OPERATION

5.1

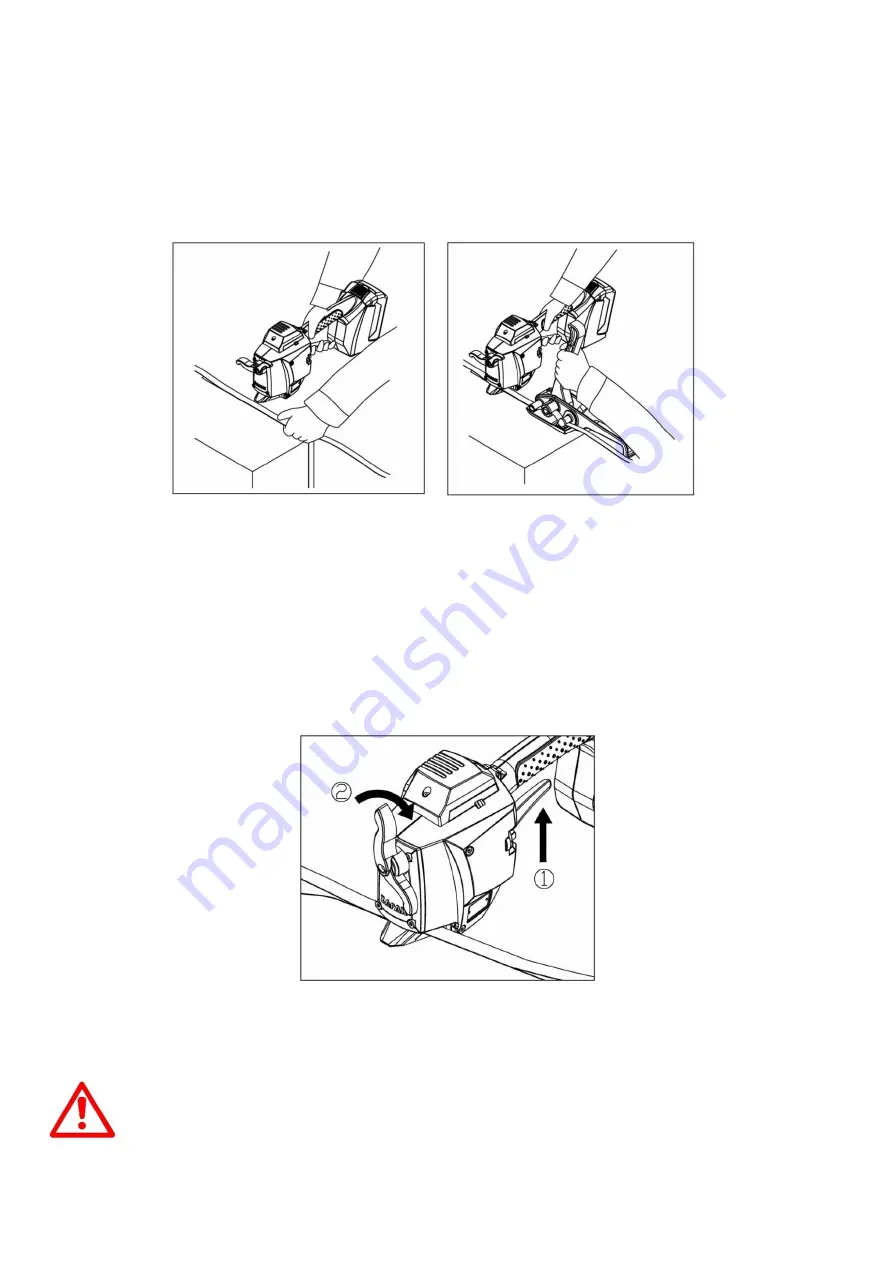

Insert strap into sealing slot

Hold the straps and make sure the straps are aligned and inserted all the way

in. See Figure 8 & 9.

FIGURE 8.

FIGURE 9.

5.2

Sealing

Lift up and

hold

the operation lever gently. Then turn the sealing lever as shown.

DO NOT RELEASE until the sealing is done and the cooling beeping noise stops.

See figure 10.

Do not force to squeeze the operation lever to the upmost. Sealing function will be

activated abno

rmally and cause insufficient sealing joint.

The surface of strap must not be stained by oil or grease. Otherwise, it will

cause insufficient sealing efficiency or failure of sealing.

FIGURE 10.

5.3

Remove the tool from straps

Turn back the sealing lever and

release the operation lever to remove the tool from

straps.

1). DO NOT ACTIVATE THE SEALING LEVER WITHOUT STRAPS.

2). Keep at least two cm between each sealing joint for multiple sealing joints.