7

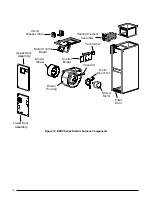

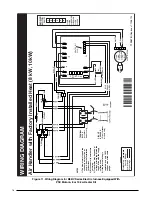

ELECTRIC FURNACE INSTALLATION

These Installation procedures are suggested for typical

electric furnace installations. Since all installations are

different from each other, the sequence of these steps may

differ from the actual installation.

Only qualified hVAC

technicians should install this furnace

.

The B5BV series electric furnace is shipped ready for

vertical upflow installation and is approved for attic,

basement, alcove/closet or crawlspace installation with

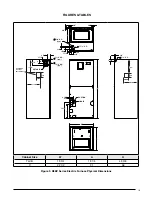

zero clearance to combustibles. See Figure 1 (page 4)

for required installation clearances.

This appliance is

only for indoor use.

• Remove the shipping crate and User’s Manual from the

equipment.

• The unit must be leveled at installation and attached to

a properly installed duct system.

• The surface that the electric furnace is mounted on

must provide sound physical support of the unit.

• The electric furnace must be installed so that all electrical

components are protected from water.

• If a louvered door is installed across the front of this

unit, the appliance must be mounted flush or behind

front edge of finished wall.

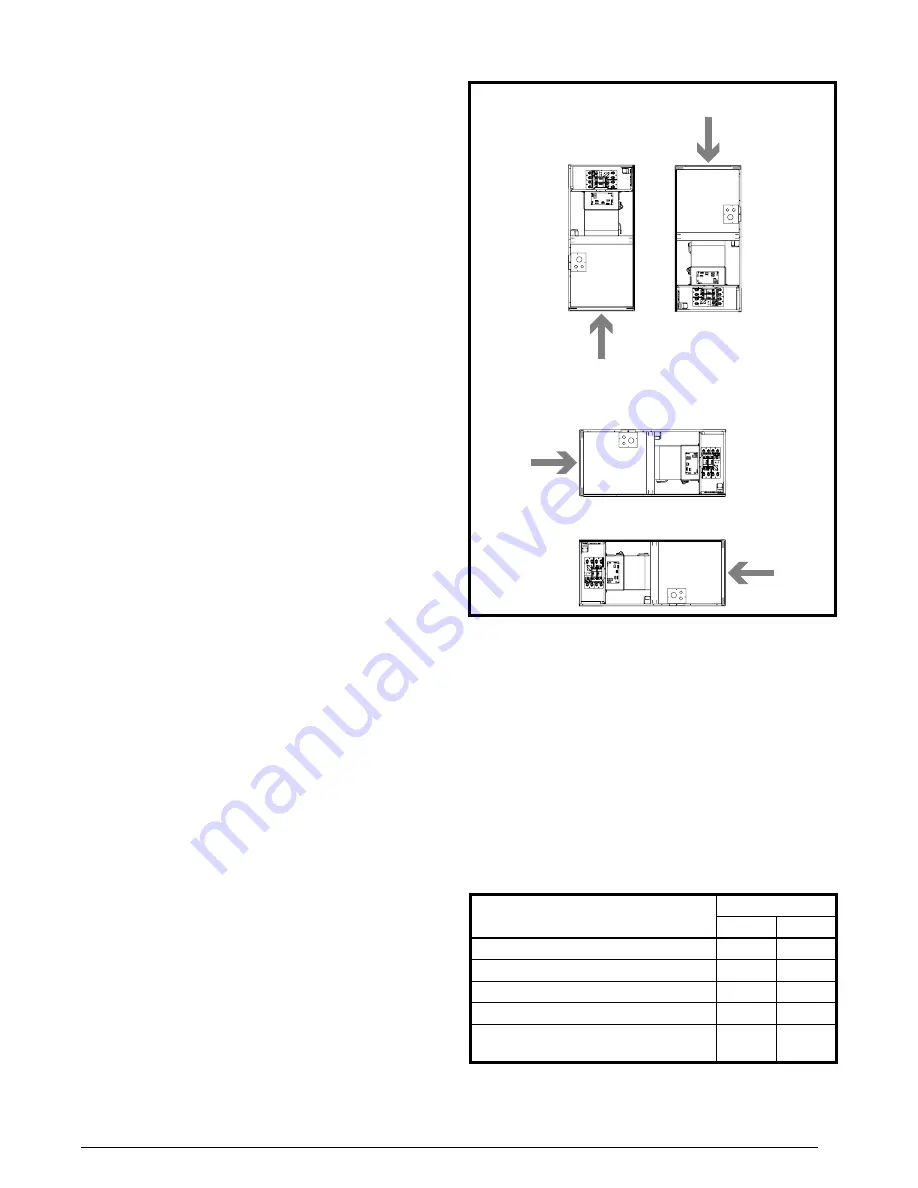

Upflow Installations

All electric furnaces are factory shipped, ready for upflow

installation. All return air must enter from the bottom of the

unit when installed in the upflow configuration. A typical

upflow unit is shown in Figure 3.

Position the electric furnace on top of the return air duct

and secure together with sheet metal screws. The screws

must penetrate the sheet metal cabinet and duct. Tape or

seal all seams if required by local code.

To attach the supply air duct to the electric furnace, bend

the perforated flanges (Figure 5, page 8) upward 90° with

a pair of wide duct pliers. Position the duct on top of the

electric furnace and secure together with sheet metal

screws. Make sure the screws penetrate the sheet metal

casing and flanges. Tape or seal all seams if required by

local code.

NOTE:

If an upflow pedestal mounting stand is fabricated

in the field, the stand must be constructed strong

enough to support the unit with all accessories installed

(approximately 130 lbs. for B-cabinet models and 200 lbs.

for C-cabinet models). The construction of the pedestal

stand must also allow for at least 235 in

2

free opening (300

in

2

for C-cabinet models) in the application. Field fabricated

upflow pedestal mounting stands must be constructed of

noncombustible materials. Position the electric furnace

on top of the mounting stand and secure together with

sheet metal screws. The screws must penetrate the sheet

metal cabinet and duct. Tape or seal all seams if required

by local code.

Downflow Installations

B5BV electric furnaces can be converted to downflow

operation by flipping an upflow unit 180°. A typical

installation of the unit in a downflow application is shown

in Figure 3.

NOTE:

Downflow installations require the use of a plenum

connector (or its equivalent) if the supply air ducts pass

through the floor of the structure. This factory supplied

accessory must be installed in the floor cavity and attached

to the supply air duct before the downflow unit is installed.

Available plenum connectors for all B5BV electric furnaces

are listed in Table 1. All return air in downflow applications

must enter through the top of the unit.

Figure 3. Installation Configurations

Return

Air

Return

Air

UPFLOW

DOWNFLOW

Return

Air

HORIZONTAL RIGHT

Return

Air

HORIZONTAL LEFT

Table 1. Optional Accessory Kits

Description

Cabinet Size

B

C

Downflow Plenum Connector, 6.25”

913840 914969

Downflow Plenum Connector, 8.25”

913841 914970

Downflow Plenum Connector, 10.25”

913842 914971

Upflow Pedestal Mounting Stand

913872 913873

Downflow Coil Adaptor

919321

919322

*919323

* Use when installing B width coil in C width cabinet