-6-

■

EPDT-042b

■

7.

Disassembly, cleaning and assembly

(1)

Since the screen is heavy in weight, when extracting the screen from the body, make

sure to secure it properly with lifting devices.

※

The screen fallen down may cause the injury.

7.1

Precautions during disassembly and inspection

Warning

(1)

Completely discharge internal pressure from the valves, lines, and equipment

before disassembly and inspection. And, cool the valve down to a level

where you can touch it with bare hands before disassembly and inspection.

※

Failure to do so may result in injury or burns due to residual pressure or

spillage around the valve.

(1)

After checking no internal pressure existed in the strainer by pressure gauge and

etc, dismount Cap

②

, and take out Screen

③

which shall be washed by

compressed air or water.

7.2

Caution during assembly

Caution

(1)

Clean the Body and gasket contact surface at the Cap.

※

Incorrect cleaning may cause the leakage from the gasket and results in burns.

(2)

Certainly replace into the new gasket whenever assembly.

※

In case using old gasket without change, the fluids may leak to the outside of

the valve.

(1)

Clean the gasket contact surface at Body

①

and Cap

②

, and mount the new

gasket at Cap

②

. At the last, assemble cleaned screen

③

at the groove on the

Cap

②

and screw to the body

①

.

8.

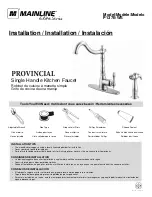

Example of piping

Figure-1

Figure-2

Figure-3