JOHNSON CONTROLS

63

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

FORM 102.20-N1

ISSUE DATE: 7/06/2016

3

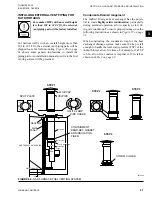

FIELD PENETRATIONS FOR PIPING AND

ELECTRICAL CONNECTIONS

Make sure all penetrations and grom

-

mets are positively sealed on the cabinet

exterior.

For small sizes such as 1/2" iron pipe,

1/2" conduit or 5/8" O.D. copper and

smaller; it is acceptable to use caulk

instead of a grommet.

Electrical conduits must be sealed in-

ternally to prevent airflow and moisture

condensation.

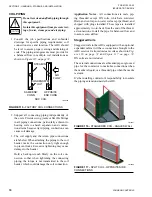

Tools Required

•

Drill motor.

•

Pilot starter bit.

•

Hole saws-approximately 2-1/2", 3-1/4" & 4-1/2"

diameter for holes.

•

Power cords as required.

Material Required

•

Neoprene grommet, 2-1/2", 3-1/4", 4-1/2" or

5-1/2" as required

(see Fig. 5-98).

•

Cold galvanized paint.

•

Paint, touchup spray, champagne, P/N 013-

03322-000 (for outdoor unit exterior only).

•

Caulk, P/N 013-02966-011 gray for indoor units

or 013-03317-040 for outdoor units with cham-

pagne paint.

•

Exacto knife.

•

Clean up supplies.

Procedure

1. Make sure any components; bulkheads or other

obstructions are disconnected from panel inside

and out.

2. Layout location and dimensions of hole opening

to be cut. Do this on both sides of double wall

panels.

3. Carefully cut correct hole size for the application

in panel, insuring cuts on both sides line up and a

smooth clean cut is made.

4. Paint raw edges of sheet metal with cold galva-

nized paint.

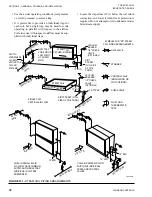

5. Select appropriate grommet for new panel hole

and cut out appropriate hole diameter for penetra-

tion with an Exacto knife.

6. After paint dries, Install grommet into panel hole

opening.

7. Apply sealant all around new hole opening behind

lip of grommet, on both sides of panel.

8. Run pipe or conduit through grommet and make

appropriate connections.

9.

All modified panels must provide integrity equal

to original equipment specifications.

10. Reconnect any components, bulkheads or other

fixtures that were disconnected from panel in step

# 1.

11. Thoroughly clean up inside and outside air unit.