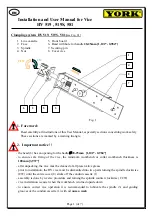

5. Dimensions and drilling of cover vice

The vice jaw and spacer should be made of fine-grained hard wood eventually plywood.

Fix the cover vice with spacer so that the top edge jaw is flush with the top of the workbench

board. That's why should be made clamping jaw with of the conduit cassette with finish

allowance. Dimensions spacer underneath the cover vice see page No.2, Fig.2a.

Fix the cover vice with spacer axially symmetrical so that spacer is not interfered a guiding

grooves of the conduit cassette.

Cover vice use after screw as template drilling hole

∅

14 for securing pins (only HV519 and

HV519S) at

∅

40 for nut. If the workbench has a collar, nut is secure sole piece and screw M8

from the inside the workbench. See Fig.2c. If the workbench has no collar it is possible nut use

not securing (that is hardly mounting clamping jaw).

Page 4 (of 7)

L

mm ["]

ks

6-8

[(0,24"-0,32"]

L=min

50

[(

L=min

2"]

6

∅

4-6

[0,16"-0,24"

]

Fig. 3

HV519(S) -

∅

14

HV 581 - xxxx

HV519(S) -

∅

40

HV581 -

∅

40

Fix the cover vice with spacer axially

symmetrical

∅

∅

S

mm ["]