WARNING: Blower and burner must never be oper-

ated without the blower panel in place.

Electrical supply to this unit is dependent upon the panel that

covers the blower compartment being in place and properly

positioned.

CAUTION: Main power to the unit must still be inter-

rupted at the main power disconnect switch before

any service or repair work is to be done to the unit. Do

not rely upon the interlock switch as a main power

disconnect.

Rollout Switch Controls

This control is mounted on the burner box assembly. If the

temperature in the burner compartment exceeds its set point,

the igniter control and the gas valve are deenergized. The

operation of this control indicates a malfunction in the combus-

tion air blower, heat exchanger or a blocked vent pipe connec-

tion. Corrective action is required. This is a manual reset control

and must be reset before operation can continue.

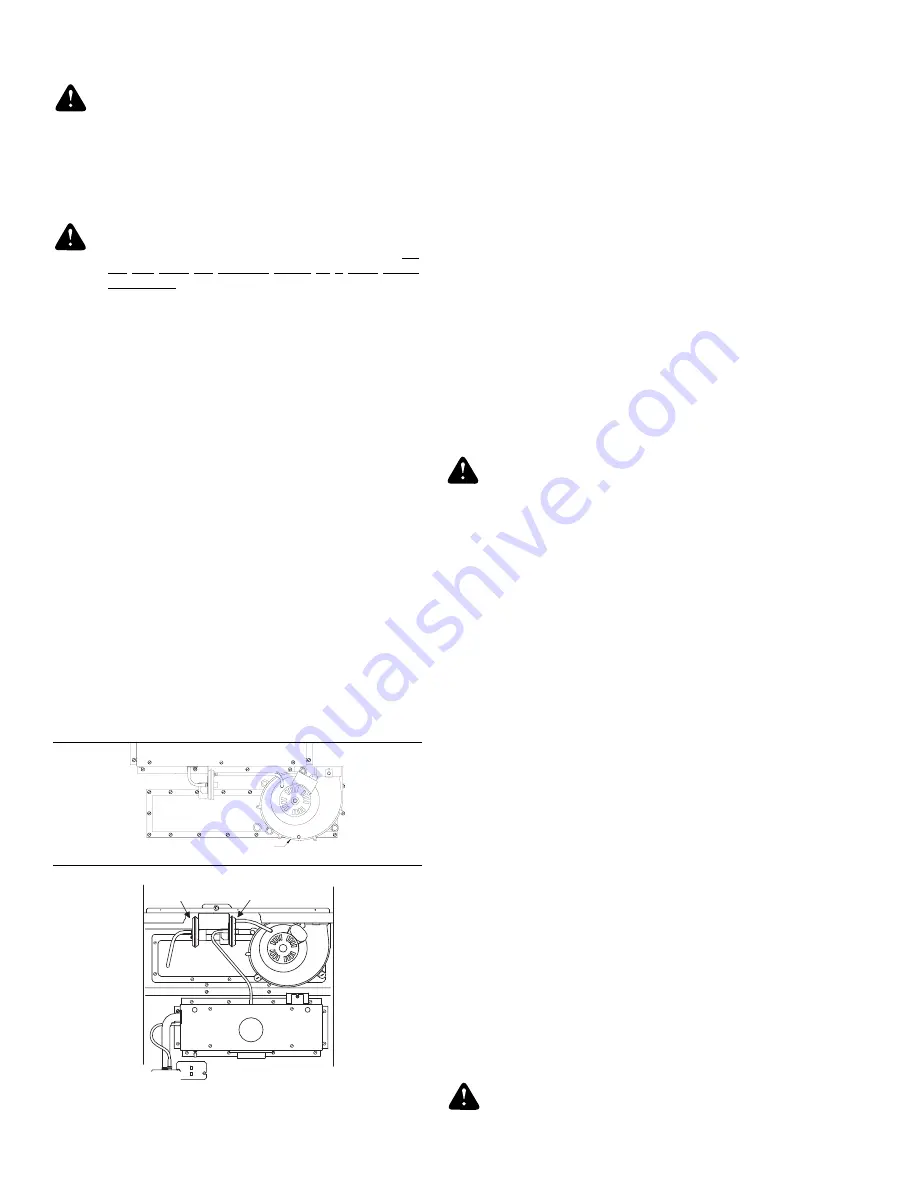

Pressure Switches

This furnace is supplied with pressure switches which monitor

the flow through the combustion air/vent piping system. These

switches de-energize the ignition control module and the gas

valve if any of the following conditions are present. Refer to

Figure 31 for tubing connections

1. Blockage of combustion air piping or terminal. (1LP)

2. Blockage of vent piping or terminal (1LP).

3. Failure of combustion air blower motor (1LP).

4. Blockage of condensate drain piping:

- Upflow units (1LP)

- Downflow/Horizontal Units

- Downflow (1LP)

- Horizontal Left (1LP)

- Horizontal Right (2LP)

Limit Control

There are high temperature limit control(s) located on the

furnace vestibule panel near the gas valve. These are automat-

ic reset control and provides over temperature protection due

to reduced airflow, such as a dirty filter.

Auxiliary Limit Controls

Downflow/horizontal units have a single limit switch mounted

on the blower assembly. This is a manual reset control and gives

high temperature protection in the event of a blower motor

failure.

START-UP AND ADJUSTMENTS

The initial start-up of the furnace requires the following addi-

tional procedures:

1. When the gas supply is initially connected to the furnace,

the gas piping may be full of air. In order to purge this air,

it is recommended that the ground union be loosened until

the odor of gas is detected. When gas is detected, imme-

diately retighten the union and check for leaks. Allow five

minutes for any gas to dissipate before continuing with the

start-up procedure.

WARNING: Be sure proper ventilation is available to

dilute and carry away any vented gas.

2. The condensate trap must be filled with water before

putting the furnace into operation. The recommended pro-

cedure is as follows:

a Disconnect the condensate drain hose from the induced

draft blower discharge.

b. Elevate this hose and fill with water using a funnel.

c. Replace the condensate drain hose and clamps.

3. All electrical connections made in the field and in the

factory should be checked for proper tightness.

IGNITION SYSTEM SEQUENCE

1. Turn the gas supply ON at external valve and main gas

valve.

2. Set the thermostat above room temperature to call for heat.

3. System start-up will occur as follows:

a. The induced draft blower motor will start and come up

to speed. Shortly after venter start-up, the hot surface

igniter will glow for about 17 seconds.

b. The ignition module will energize (open) the main gas

valve for seven seconds.

c. After flame is established, the supply air blower will

start in about 30 seconds.

NOTE: Burner ignition may not be satisfactory on first start-up

due to residual air in line.

4. With furnace in operation, paint the pipe joints and valve

gasket lines with a rich soap and water solution. Bubbles

indicate a gas leak. Take appropriate steps to stop the leak.

If the leak persists, replace the component.

WARNING: DO NOT omit this test! Never use a flame

to check for gas leaks.

CHECKING GAS INPUT (NATURAL GAS)

1 L P

2 L P

DOWNFLOW

HORIZONTAL

2LP

1LP

FIGURE 31 -PRESSURE SWITCH TUBING ROUTING

BURNER BOX

1LP

INDUCTED DRAFT

BLOWER

UPFLOW

650.75-N4U

20

Unitary Products Group

Содержание 65075-N4U

Страница 29: ...UNIT WIRING DIAGRAM UPFLOW 650 75 N4U Unitary Products Group 29...

Страница 30: ...UNIT WIRING DIAGRAM DOWNFLOW HORIZONTAL...

Страница 31: ...NOTES 650 75 N4U Unitary Products Group 31...