8-20

8-21

IM 11Y01B01-01E-A 6th Edition :Feb 13, 2013-00

<8. VALIDATION AND CALIBRATION>

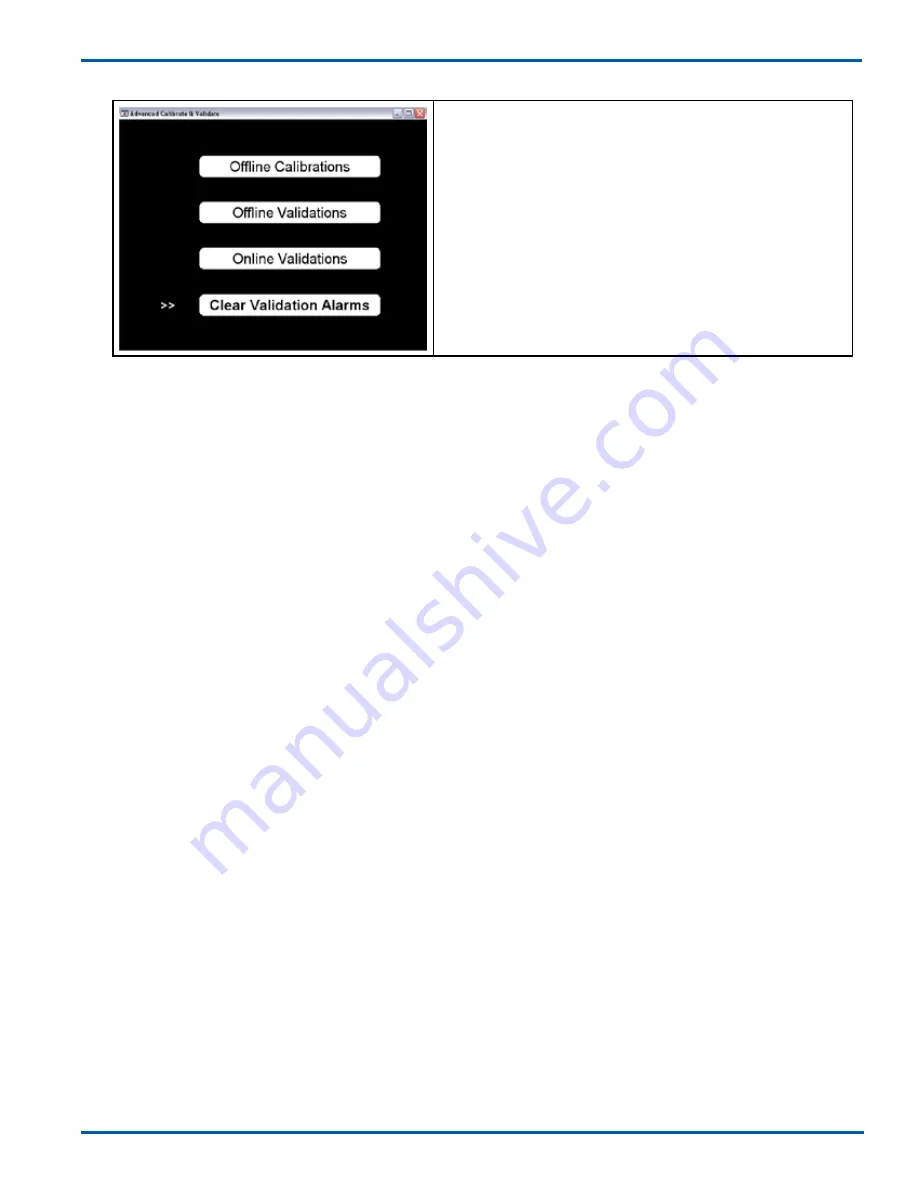

If the validation fails, repeat the validation after

checking the parameters are correct and

ensuring there is sufficient purge gas time. If the failure

is due to a known non-related event (such as incorrect

validation gas value or non-functioning valve) then the

validation alarm can be cleared as shown.

8.6 Performing Automated On-Line Validation

This will require the appropriate automatic valves (solenoid valves and/or pneumatically actuated valves), tubes

and tubes fittings such that the integral on-line check gas flow cell can be purged with either normal purge gas

(typically Nitrogen) or the check gas (instrument air is acceptable for Oxygen analyzers).

The analyzer can drive one 24 VDC solenoid operated valve (external, optional valve or customer supply) with a

max 10W rating. Typical Automatic On-Line validation will use one of the following approaches:

• A 3-way solenoid actuated valve that directly switches between the purge gas (typically nitrogen) and the

check gas.

• A 3-way solenoid valve that is used to pilot a pneumatically actuated 3-way ball valve

• A 3-way solenoid valve that is used to pilot a pneumatically actuated manifold style valve (such

as the Swagelok T series or Parker R-Max or even NESSI platforms)