3.5 Presenting the Required Specifications to the Resistor Manufacturer

3-15

3

Selecting a Dynamic Brake Resistor

3.5

Presenting the Required Specifications to the Resistor Manufacturer

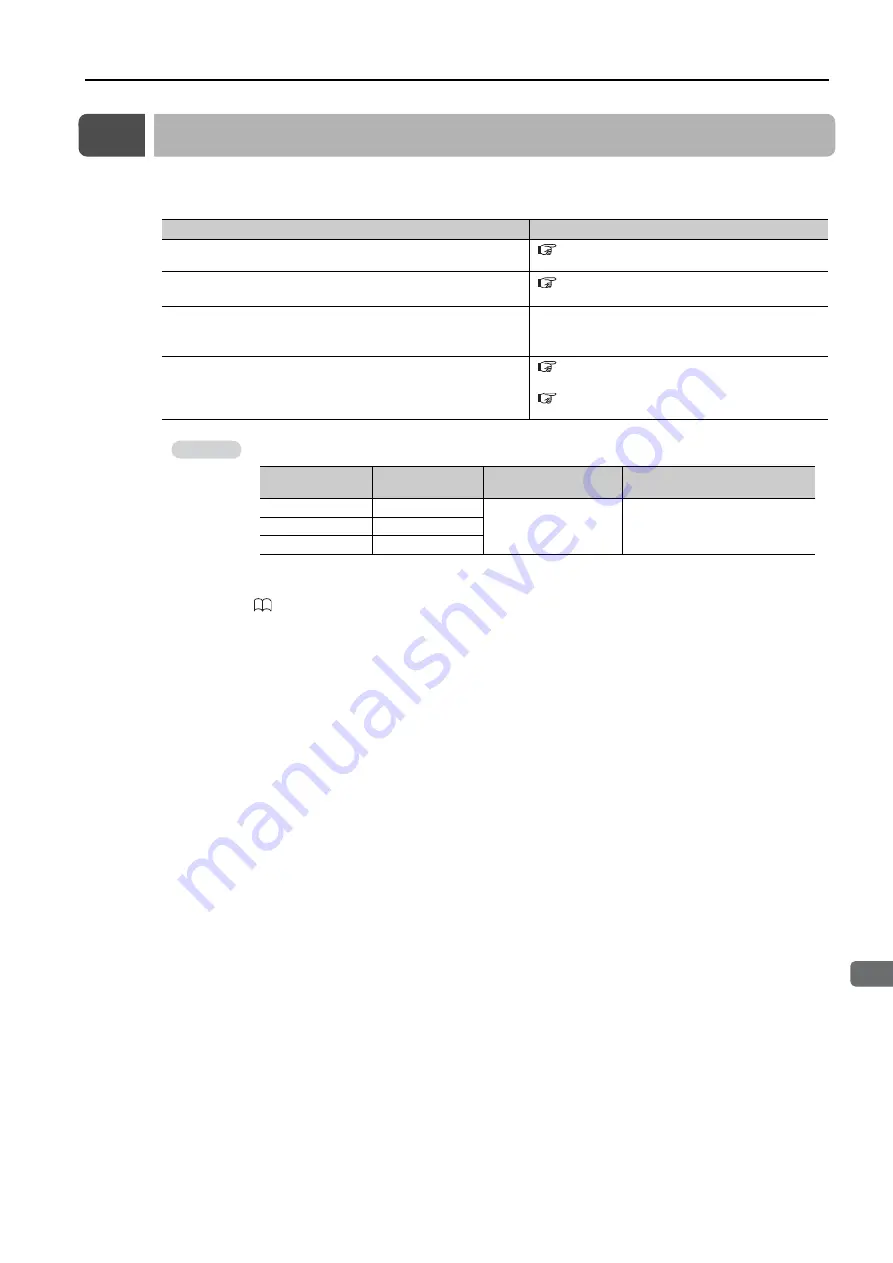

Provide the following information to the manufacturer of your resistors and select a dynamic

brake resistor that is appropriate for the required specifications.

Required Information for Resistor Selection

Reference

Resistance [Ω]

3.3 Determining the Resistance of the Dynamic

Resistor energy consumption for one operation of the

dynamic brake [J]

3.4 Calculating the Energy Consumption of the

Number of dynamic brake operations (estimated number of

emergency stops required during the product life of your

system)

−

Wire sizes and crimped terminals

Note: The applicable wire sizes depend on the SERVOPACK

model.

4.2.1 Terminal Symbols and Terminal Names

4.2.2 Wire Sizes and Tightening Torques

Resistor Selection Example for a Dynamic Brake That Operates 1,000 Times

Refer to the following manual for the external dimensions of the dynamic brake resistor and

other parts in the selection example.

Σ

-7-Series Peripheral Device Selection Manual (Manual No.: SIEP S800001 32)

Example

Resistor Energy

Consumption

Model

Inquiries

Manufacturer

1,000 J max.

RH120 Series

Yaskawa representative

Iwaki Musen Kenkyusho Co., Ltd.

2,000 J max.

RH220 Series

10,000 J max.

RH500 Series