Every 250 Hours of Operation

Perform the following maintenance every

250 hours of operation.

• Touching-Up the Stern-Drive Paint and

Spray with Corrosion Guard

• Retorqueing the Rear Engine Mounts

• Changing the Stern-Drive Oil

Touching-Up the Stern-Drive Paint

and Spray with Corrosion Guard

Corrosion damage that results from

improper application of anti-fouling paint will

not be covered by the warranty.

Painting vessel hull or vessel transom:

Anti-fouling paint may be applied to the

vessel hull and the vessel transom.

NOTICE: NEVER paint the anodes or Y-

CaPS electrode. Painting these

components will render them ineffective as

galvanic corrosion inhibitors.

NOTICE: Use copper-based paint as anti-

fouling protection for the vessel hull or

vessel transom, as long as it is not prohibited

by law in the area where the vessel will be

operated. If using copper- or tin-based anti-

fouling paint, avoid an electrical

interconnection between the Yanmar

Product, Anodic Blocks, or Y-CaPS and the

paint by allowing a minimum of 40 mm (1-1/2

in.) of UNPAINTED area on the transom of

the vessel and around these items.

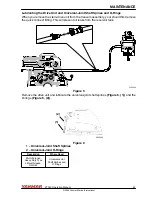

(2)

(1)

0006341

Figure 11

1 – Painted Vessel Transom

2 – Minimum 40 mm (1-1/2 in.) of

unpainted area around transom

assembly

NOTICE: The drive unit and transom

assembly can be painted with a good quality

marine paint or an anti-fouling paint that

does not contain copper or any other

material that could conduct electrical

current. NEVER paint drain holes, anodes,

Y-CaPS or items specified by the vessel

manufacturer.

NOTICE: NEVER wash the stern-drive with

a power washer because it can damage the

coating on the reference wire and increase

corrosion.

Retorqueing the Rear Engine

Mounts

See Torqueing the Rear Engine Mount Bolts

on page 44.

Changing the Stern-Drive Oil

Note: The Stern-Drive oil must be changed

every 250 hours or every year, whichever

comes first.

MAINTENANCE

46

ZT350 Operation Manual

© 2008 Yanmar Marine International