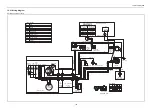

9. Cooling water system

174

9.7.5 Cautions for assembling

Observe the following cautions for handling.

• Do not use gasoline or solvents.

1) gasoline 2) ester 3) benzol 4) battery fluid 5) liquids at 70°C or greater or engine oil

• Never run when there is no water in the bilge.

Check to be sure that the strainer is in the water before turning on the switch.

• Keep the cord terminal away from the water. Water inside the motor or switch may lead to damage.

When the insulation around the cord is damaged, water can seep in to the wires; thus, care should

be taken not to scratch or nick the cord.

• When the pump has not been used for a long

period of time, the inside of the pump will be dry

and it may not operate properly at first. If after 10

seconds the pump is not working, turn off the

switch and prime the pump before trying again.

(Never run the pump dry for period of greater than

10 seconds.)

• Replace the diesel engine oil only after the engine

has been stopped for a period of 30 minutes (oil

temp. 20-70°C). Whenever possible refrain from

operation when the oil temperature is below 15°C or above 50°C.

• Bilge water left in the hose or inside the pump can freeze, and care should be taken to see that any

excess bilge is completely discharged. If bilge water should freeze, and care should be taken to

see that any excess bilge is completely discharged. If bilge water should freeze inside the hose or

pump, it should be completely melted before starting up the pump. When the temperature inside

the pump is low, it will take a longer time for the pump to operate. (0°C, 5-10 seconds.)

• Keep the pump in a dry place away from rain or other water.

• Use the regulation hose; do no use thin vinyl hose or hose which is not heat-resistant.

• The pump cannot be used to drain off rainwater or large quantities of flood water. This pump can

be operated continuously for a period of 10 minutes.

• Do not use the pump for showering.

If the pump outlet is deformed for showering, the increase in water pressure will increase the load

on the motor and cause motor seizure.

• When sludge has built up in the bilge to be drained, position the strainer about 20 cm above the

sludge. When the pump is stopped, be sure there is sludge remaining inside the pump housing.

• The specific gravity for the battery fluid is 1.25.

• Refer to your local dealer for impeller replacement.

The local dealer will perform the following.

The impeller replacement kit includes one impeller and 3 films for adjusting the side gap. If after

replacing the impeller the pump does not drain, place side gap adjustment washers underneath the

bottom plate to adjust. Select the number of films used in accordance with the following. (When the

pump is draining, the electric current load is about 10A for 12V and 5A for 24V. The pump operates

efficiently at these electric current loads.)

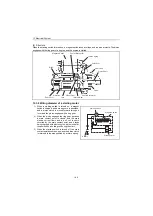

Steps for replacement

1) Remove the impeller plate by taking out the M4 screws (4) and opening the top of the diaphragm

switch.

(Screw lock has been applied to the screw, and a dryer should be used to heat the screw before

removing it.)

2) Clean the inside of the pump.

3) Grease the plate, impeller, and film for side gap adjustment, and then reassemble the pump by

inserting first the film plate and then the impeller.

Содержание 3YM20

Страница 1: ...M9961 03E100 ...

Страница 41: ...2 Inspection and adjustment 26 Cylinder head Bracket Fuel filter Fuel pipe Fuel injection pump Clamp Fuel pipe ...

Страница 154: ...6 Fuel injection equipment 139 6 1 3 Fuel injection pump structure Section of a fuel injection pump governor for 3YM30 ...